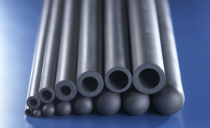

Hexoloy® Silicon Carbide Tubes for Protecting Your Temperature Sensor

Saint-Gobain Ceramic Materials has been a major contributor to the Silicon Carbide thermocouple protection tube industry for over 20 years. Improvements in the sintering process have led to unprecedented levels of purity, which have improved upon the material’s performance. In the harshest, most corrosive and abrasive environments, Hexoloy will outperform traditional commercially available ceramics and metal alloys.

Hexoloy® is produced by pressure-less sintering of submicron silicon carbide powder in a proprietary extruding process. The sintering process results in a self-bonded, fine grained (less than 10 μm) SiC product. Densities of fired parts are consistently in excess of 95% of the theoretical density of silicon carbide (3.21 g/cm3). Extremely hard and lightweight, Hexoloy® has a high resistance to corrosion, high temperatures and thermal shock while also having a high thermal conductivity. This makes Hexoloy® an ideal material for temperature sensor tubes in a variety of traditionally challenging environments such as incinerators, chemical processing and furnaces.

Due to its high density, low porosity and chemical inertness, Hexoloy® has universal corrosion resistance, meaning that it is suitable for almost all chemically corrosive environments. It has superior oxidation resistance due to a silicon dioxide film that forms after sintering. It can be used in the presence of hot liquids or gases, strong acids, bases or oxidizers. Since it is made without binders, Hexoloy® thermocouple protection tubes will not contaminate process media making it suitable for high purity processing applications.

A high thermal conductivity, five times that of alumina, means that small temperature changes can be accurately captured with high sensing speed and no hysteresis. Hexoloy also has a low coefficient of thermal expansion enabling its use in extremely high temperatures up to 1,950°C (dependent on application). It can withstand sudden temperature changes with a resistance to thermal shock more effectively than tungsten carbide, aluminum oxide and Reaction Bonded silicon nitride. In general, these thermal properties make Hexoloy® a promising alternative to ductile metals in high temperature applications.

In addition to its excellent chemical and thermal properties, Hexoloy® has exceptional hardness of 2,800 kg/mm2. This makes it 50% harder than tungsten carbide. With a specified wear rate (pin on disc) of SiC versus SiC 1x10-9 mm2/kg, coefficient of friction (pin on disc) SiC versus SiC 0.2, Hexoloy is excellent for applications involving high abrasion or sliding wear. Even at temperatures as high as 1,650°C in air, or up to 1,950°C in argon/nitrogen, Hexoloy® can withstand abrasion, making it ideal for waste incinerators, gas, oil, coal or biomass fired chambers. Yet, Hexoloy® is also light, weighing 40% as much as steel and about the same as aluminum.

Hexoloy has an as-fired surface finish of 32-64 micro-inches. The excellent surface finish of Hexoloy combined with tight dimensional control leads to parts that require little to no machining or finish grinding. Mass production of thermocouple tubes with complex shapes by extrusion and pressure forming are available. Consolidation by sintering at temperatures above 2,000°C results in a single-phase, fine-grain silicon carbide product that’s extremely pure and uniform, with virtually no porosity. Hexoloy® tubes for temperature sensors are available in a variety of diameters and lengths specific to the parameters and constraints of the application.

In summary, the combination of Hexoloy®’s thermal, chemical and physical properties makes it uniquely qualified for protective temperature sensor tube applications in challenging environments. These properties, as well as Hexoloy’s high thermal conductivity and low thermal expansion make it the perfect material for protecting a temperature sensor in a tight space while still providing a quick and accurate thermal response.

As technology advances and chemical processors, incinerators and other systems become more precise and efficient, materials involved with those systems must necessarily evolve in performance as well. Hexoloy® is a next-generation material designed to perform in a variety of environments, at high temperatures, with precision. It provides the performance and protection thermocouples need in next-generation systems.

Related Content

Specialty Ceramics

Saint-Gobain Performance Ceramics & Refractories’ extensive range of specialty ceramic products – ideal for use in the harsh environments typical in broad...

Silicon Carbide (SiC)

Silicon carbide ceramics for a range of industries, including electronics.

Hexoloy Silicon Carbide Material

Discover Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SiC - a pressure-less, sintered form of alpha silicon carbide.

Hexoloy® SE Thermocouple Protection Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for thermocouple sensor protection.