Wear Resistant Linings for Sinter Production

Iron ore is the key raw material for making iron and steel. However, it cannot be used in its unprocessed state. Sinter production is a thermal process that converts the mixture of agglomeration iron ore fines, coke, and fluxes into a sinter—the primary feed material of suitable composition and granularity for the induction blast furnace.

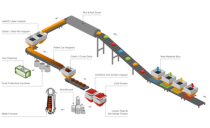

Process Cycle of Sinter Production

The key processes during sinter production involve homogenizing high throughputs of raw materials, loading, and heating the sinter mix onto the sinter strand, feeding the crystallized sinter cake into a crash deck sizing and feeding the hot screens, cooler and then further cold screening of the sinter before it is sent to the Blast Furnace.

Wear Sinter Production's Nightmare

Wear resistant Linings

Wear resistant linings safeguard these critical components against wear and abrasion. A proper selection of wear resistant linings can significantly improve the service life of the sinter plant while ensuring a high purity sinter feed with minimum contamination due to wear. Wear resistant linings are a cost effective solution to improve the overall efficiency of the sinter production, besides extending the equipment lifetime and achieving maximum operation levels.

Thanks to their excellent wear and corrosion resistance, superior thermal shock resistance, low thermal expansion, high hardness, and ability to withstand harsh service environments, Saint Gobain’s extensive range of ceramic based wear resistant linings are a proven, cost effective solution for routine applications in sinter production. For these advantages, refractory materials outperform conventional materials like abrasion resistant steels, rubbers, and plastics.

Portfolio of Wear Resistant Solutions

Saint Gobain’s high performance wear resistant linings are based mostly on aluminum oxides and silicon carbides. They are pre-engineered for efficiently reducing wear in severely demanding applications. Some state-of-the-art economic solutions spanning a versatile range of product specific applications include:

- Durafrax® Alumina Materials: the workhorse for wear resistant linings; a high grade, cost effective, extremely fine grained alumina with superior wear resistance against fine particle abrasion.

- Hexoloy® SiC Materials: one of the hardest, high performance wear resistant lining existing. It is a self-bonded, fine grained, and lightweight sintered form of alpha-silicon carbide with excellent sliding wear, corrosion, and thermal shock resistance. It is ideal for high temperature applications with a maximum use temperature of 1,900°C.

- Cryston® SiC Materials: a high performance nitride bonded silicon carbide, ideal for chemically harsh environments involving severe wear, erosion, and high operating temperatures. Its maximum use temperature is 1,590°C. It can be cast and pressed into complex geometries for challenging refractory applications.

- ZAC-Corguard® Refractory Materials: a dense, electrically fused combination of zirconia, alumina, and silica. Its interlocked grains and impervious structure make it an ideal wear resistant solution against heavy impact and sliding abrasion, and corrosion by slags, acids, and other molten materials in the sinter production.

- Refrax® 20 SiC Materials: a nitride bonded silicon carbide, having a high abrasion resistance and a very low thermal expansion (high thermal stability), with a maximum use temperature of 1,590°C.

- Norfrax® RB SiC Materials: a high performance, fine grade reaction bonded (RB) silicon carbide wear resistant material with excellent thermal shock resistance and structural stability, ideal for applications with severe wear. Prepared via sintering, it possesses a high degree of formability, making it ideal for complex lining demands.

- Durastrike™ ZTA Refractory Materials: a special class of dense, high performance zirconia toughened alumina, ideal for severe impact wear applications, uniquely preventing micro-crack propagation via zirconia impregnation.

- Wearfrax® Monolithics: a class of monolithic castables based on silicon carbide and alumina, having high wear resistance, and impressive ability to withstand thermal shocks, both in low and high temperature applications.

If you would like to speak with one of our experts about using one of these wear-resistant linings in your sinter production workflow, simply contact us.

Related Content

Wear Resistant Technologies

Saint-Gobain Performance Ceramics and Refractories have developed a range of wear resistant technologies using alumina oxides (Al2O3 and ZTA) as well as...

Sinter Plant

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for demanding sinter plant...

Hexoloy Silicon Carbide Material

Discover Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SiC - a pressure-less, sintered form of alpha silicon carbide.

Wear Resistant Linings for Sinter Production

Sinter production is a thermal process that converts the mixture of agglomeration iron ore fines, coke, and fluxes into a sinter.