Spezifikationen

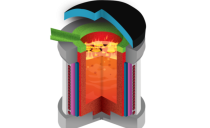

NORFLOW® Self-Flow Castables are engineered for easy installation. Customers simply need to prepare their mix and pour into the work area. The product will flow automatically into all zones without needing tools like vibrators. Self-flow castables suit a range of specific areas, such as coil grout in coreless induction furnaces and working linings for inductors, ladles, pouring furnaces, and more. They come in various compositions to suit specific melt chemistries, ensuring superior performance in high-temperature and erosive environments.

| Aggregatbereich | Produktname | METAL | Chemische Zusammensetzung | |||

| Eisen (I), Stahl (S), Kupfer / Messing (CB), Zink (Zn), Aluminium (AL) | Al2O3 % | SiO2 % | MgO % | SiC % | ||

| Spulenputz | NORFLOW A 337 | I / S / CB / Zn / AL | 92 | 1 | ||

| Verschleissfutter | NORFLOW A 1167 | I | 87 | 8 | ||

FAQ

Are NORFLOW® Self-Flow Castables suitable for ladle relining?

Many customers using ladles have already switched to NORFLOW® castables – particularly NORFLOW® 973 - citing ease of installation and increased performance in ladle applications.

What are NORFLOW® Self-Flow Castables?

NORFLOW® Self-Flow Castables are advanced refractory materials designed for easy installation in high-temperature applications, providing thermal shock resistance, high mechanical strength, and outstanding durability.

Where are self-flow castables used?

Self-flow castables are used in coreless induction furnaces, ladles, pouring furnaces, and aluminium production to enhance performance, reduce downtime, and ensure longevity.

Fallstudie

Verwandte Artikel

Gießerei

Saint-Gobain Performance Ceramics & Refractories nutzt sein umfassendes Know-how, um innovative, zuverlässige Feuerfestlösungen für alle Schmelzverfahren...

Verbesserte Leistung der feuerfesten Auskleidung von Pfannen durch...

Entdecken Sie unsere Norflow® selbstfließende gießbare Feuerfestproduktlinie mit längerer Lebensdauer.

Induktionstiegelofen

Das umfangreiche Produktportfolio von Saint-Gobain Performance Ceramics & Refractories für den Bereich Induktionstiegelöfen unterstützt die Kunden bei der...

Induktor

Der Induktor ist ein wesentlicher Faktor bei der Installation und der Leistungsfähigkeit eines Ofens. Saint-Gobain Performance Ceramics & Refractories...

Pfannen & Sonstiges

Saint-Gobain Performance Ceramics & Refractories bietet eine Reihe von Lösungen, die die Sicherheit, Effizienz und einfache Installation von Pfannen und...

Vergieß- und Warmhalteofen

Saint-Gobain Performance Ceramics & Refractories bietet Lösungen für eine breite Palette von Vergieß- und Warmhalteöfen an, wobei Faktoren wie Größe...

Ähnliche Produkte

HeatKing monolithische Auskleidungslösung

Das HeatKing™-Sortiment von Saint-Gobain Performance Ceramics & Refractories an hochleistungsfähigen Feuerfestprodukten ist für den Einsatz unter extremen...

NORVIBE Trockenvibrationszement

Saint-Gobain Performance Ceramics & Refractories Trockene Vibrationsmassen (DVC) NORVIBE™ wurden entwickelt für eine einfache Installation, hervorragende...

NORCAST® Gussmassen

NORCAST® Gießprodukte von Saint-Gobain Performance Ceramics & Refractories entwickelt, um eine einfache Installation, eine optimierte Abbindezeit und eine...

NORTOP Topping-Mischungen

Saint-Gobain Performance Ceramics & Refractories' umfassendes Sortiment an NORTOP™ Topping-Mischungen ist für den Einsatz im oberen Bereich der...

NORCOIL™ Zementmischungen

Die Saint-Gobain Performance Ceramics & Refractories NORCOIL™ Produktreihe wurde speziell zum Schutz der Spule eines Induktionstiegelofens entwickelt.

NORRAM Stampfmassen

Das NORRAM™-Sortiment von Saint-Gobain Performance Ceramics & Refractories an Nass- und Trockenstampfmassen ist für eine Vielzahl von Schmelzanwendungen...

NORSHAPE Vorgeformte Bauteile

NORSHAPE™ Produkte weisen eine homogene und streng kontrollierte Mikrostruktur auf, die dazu beiträgt, die Ofenlebensdauer zu verlängern und die...

NORSHOT Spritzbetonmassen

Die Spritzbetonmassen der NORSHOT™-Reihe verfügen über optimierte Klebesysteme, um den Rückprall zu reduzieren und die Haftung während der Installation zu...