About the product

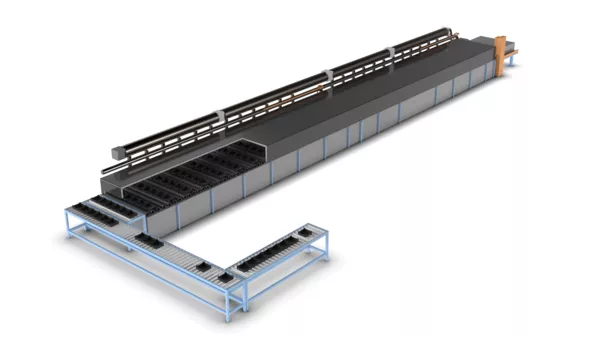

PowerCeram™ Rollers offer outstanding chemical resistance, particularly against corrosive substances like Lithium compounds, ensuring longevity and consistent performance. They are engineered to withstand high service temperatures up to 1,750°C and boast exceptional mechanical strength, including excellent load-bearing capacity and straightness for stable conveying. With precision engineering that minimizes surface roughness and wear, these rollers come in customizable dimensions up to 4000 mm in length and 70 mm in diameter, featuring premium material options like Hexoloy® SE and Silit® SK to meet diverse application needs.

Eigenschaften und Vorteile

Vorteile

Materialeigenschaften

Anwendungen

- Dichtes Material

- Ausgezeichnete chemische Beständigkeit

- Hervorragende Verschleißfestigkeit

- Variable Abmessungen bis zu 3,700 mm Länge

- Minimierte Durchbiegung

- Fortschrittliches Design

| SiC-Gehalt | max. Betriebstemperatur | Dichte | Scheinbare Porosität Vol. | Bruchmodul | Wärmeausdehnung αRT 1,100 °C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| Silit® SK | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

| Silit® SKD | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

Geeignet für verschiedene Anwendungen in der Sanitärindustrie, Automobilindustrie (DPF/GPF) und der Wärmebehandlung von Lithium-Ionen-Pulver.

Want to know more?

Achieve your goals with our customized industrial ceramic solutions. Contact us today to learn more!

Dokumente

Brochures & Flyers

Ceramic-Systems-Ceramic-Rollers-for-Electric-Vehicles-brochure-A4-EN-web

Lithium-ion batteries are ubiquitous in electric vehicles and storage, handheld electronics, medical equipment, power tools, and many other products.

PDF | 775.81 KB

Data Sheets (TDS)

Anal SKDH

Reaktionsgebundenes oder silikonisiertes Siliciumcarbid wird aus porösem Kohlenstoff und geschmolzenem Silicium durch additives Formen, Gießen oder

PDF | 113.29 KB

Related Content

Redaktion

PowerCeram

Advanced ceramic solutions designed for thermal shock and chemical corrosion resistance.

PRODUKT

PowerCeram Saggers

Explore the benefits and features of PowerCeram® Saggers for CAM Processing.