About the product

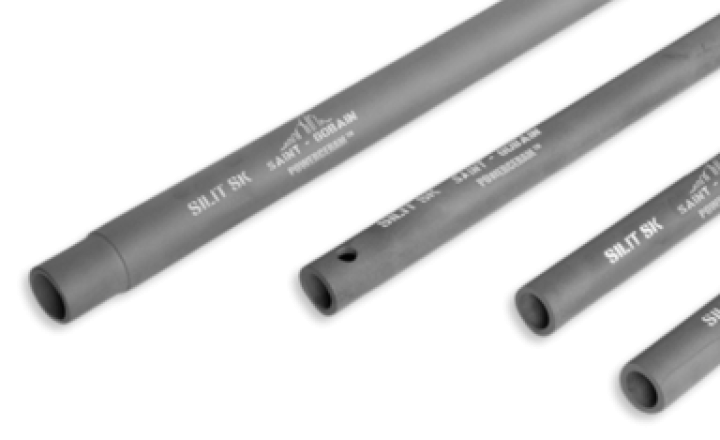

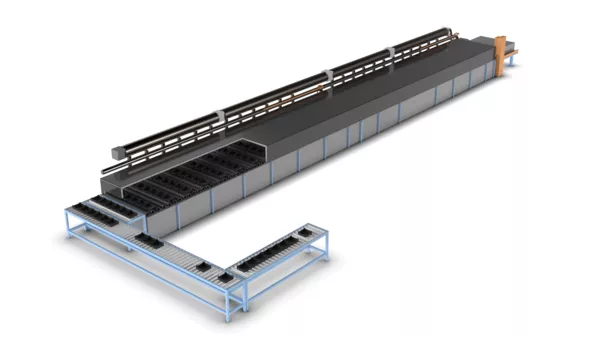

PowerCeram™ Rollers offer outstanding chemical resistance, particularly against corrosive substances like Lithium compounds, ensuring longevity and consistent performance. They are engineered to withstand high service temperatures up to 1,750°C and boast exceptional mechanical strength, including excellent load-bearing capacity and straightness for stable conveying. With precision engineering that minimizes surface roughness and wear, these rollers come in customizable dimensions up to 4000 mm in length and 70 mm in diameter, featuring premium material options like Hexoloy® SE and Silit® SK to meet diverse application needs.

Features and Benefits

Benefits

Material Properties

Applications

Reduced Breakage Risk

Extends roller lifespan and minimizes operational downtime.

Extends roller lifespan and minimizes operational downtime.

Chemical Resistance

Prevents weakening and loss of roundness, ensuring consistent performance.

Prevents weakening and loss of roundness, ensuring consistent performance.

High-Temperature Reliability

Ensures performance under extreme thermal conditions.

Ensures performance under extreme thermal conditions.

Precision Engineering

Enhances operational efficiency and product quality.

Enhances operational efficiency and product quality.

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modulus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| Hexoloy® SE | > 98 | 1,750 | 3.05 | 5.10 | 280 | 270 | 4.02 |

| Silit® SK | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

| Silit® SKD | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

Lithium-Ion battery Cathode Active Material production and Anode Active Material (AAM) production.

Want to know more?

Achieve your goals with our customized industrial ceramic solutions. Contact us today to learn more!