Refractory Bricks

Engineered Ceramic Shapes

Saint-Gobain Performance Ceramics and Refractories offer a wide range silicon carbide (SiC) refractories blocks, developed a better performing material with industry-leading service life.

Copper

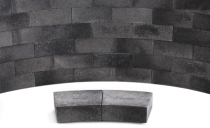

Hot Face Bricks

Hot Face Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of silicon carbide hot face bricks for copper furnaces.

Impact Bricks

Impact Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of impact bricks for the charging section of copper furnaces.

C104

C104

Discover the C104 fused cast refractory – an ideal solution for the most demanding furnace applications.

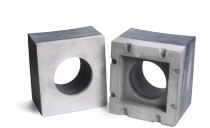

Burner Blocks and Burner Tubes

Burner Blocks and Burner Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of burner blocks and burner tubes for copper furnaces.

Tap Hole Blocks

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

Waste to Energy

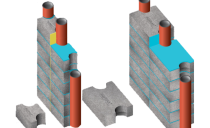

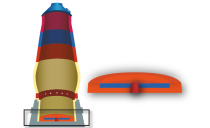

Belly Brick System

Belly Brick System

Discover Saint-Gobain Performance Ceramics & Refractories’ belly brick system - straightforward protection for single tube walls with no metallic fixing ...

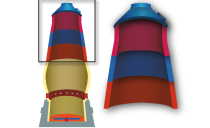

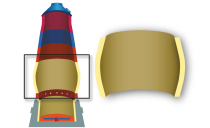

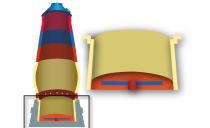

Ironmaking

Al2O3-SiC-C Bricks

Al2O3-SiC-C Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Al2O3-SiC-C bricks – ideal for use in torpedo cars.

Upper and Lower Stack Products

Upper and Lower Stack Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of brick and shotcrete solutions for the upper and lower stack.

Belly and Bosh Products

Belly and Bosh Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide or corundum-based bricks – ideal belly and bosh solutions.

Hearth Products

Hearth Products

Discover Saint-Gobain Performance Ceramics & Refractories' Coranit Ceramic Cup - widely recognized as the ideal solution for extended hearth service life.

Ceramic Pad Products

Ceramic Pad Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of pad bricks – available in circular or herringbone designs.

Steelmaking

Magmalox Bricks

Magmalox Bricks

Magmalox® a range of products manufactured by melting alumina ceramic power in an Electric Arc Furnace (EAF) at temperatures ranging from 2,000-2,500⁰C.

Carbon Black

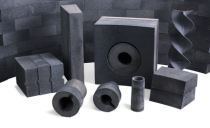

Carbon Black Reactor Refractory Products by Zone

Carbon Black Reactor Refractory Products by Zone

Discover a wide range of shaped and unshaped refractories to meet specific cost and performance targets for any reactor.

Systems for Kilns and Furnaces

Alundum, Alfrax, Mullfrax, and Zirnorite Refractories

Alundum, Alfrax, Mullfrax, and Zirnorite Refractories

Discover Saint-Gobain Performance Ceramics & Refractories’ range of specialized refractory bricks and shapes – ideal for the most extreme high-temperature ...

Aluminum

Refrax ARC Block

Refrax ARC Block

Refrax ARC is a silicon nitride bonded refractory. It has exceptionally high strength combined with greater resistance to thermal shock.

Advancal Blocks

Advancal Blocks

With their outstanding corrosion resistance, new Advancal® blocks last longer than conventional blocks.

Cryston® Max bricks

Cryston® Max bricks

The charging areas experience very high wear due to impact and abrasion that occurs when material is loaded into the furnace.

Cast Refrax

Cast Refrax

Cast Refrax silicon nitride bonded silicon carbide refractory,is chemically inert to most materials.