Steelmaking

Advanced Refractory Products Supporting Steelmaking

Steelmaking processes operate under conditions that demand unwavering material performance. High temperatures, corrosive environments, and continuous thermal cycling place significant demands on every component involved. Refractory materials must not only endure these stresses but also contribute to consistent process stability over time. With expertise in refractory composition, thermal behaviour, and furnace refractory lining engineering, Saint-Gobain Performance Ceramics & Refractories develops products suited to the functional requirements of steelmaking operations. Each of our solutions is tailored to the different challenges in iron and steel production, supporting long-term process efficiency and equipment integrity.

Adapted Solutions

We offer tailored refractory technologies that integrate seamlessly into the demanding environments of iron and steelmaking. At Saint-Gobain Performance Ceramics & Refractories, a comprehensive range of refractory products and furnace solutions is available for iron and steelmaking equipment. Our engineered materials combine chemical stability, mechanical strength, and thermal efficiency to ensure consistency throughout every stage of production, while our high-performance refractories for DRI shaft furnaces deliver exceptional wear resistance and hydrogen corrosion protection under high-temperature reducing atmospheres. As low-carbon iron and steelmaking continues to evolve, we remain committed to innovating refractory technologies that enable producers to achieve cleaner, more sustainable operations.

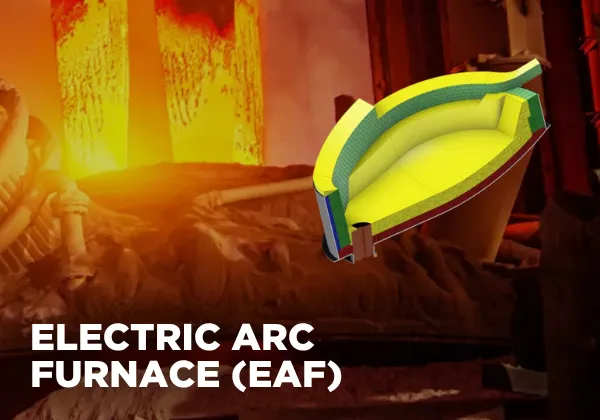

Electric Arc Furnace (EAF)

EAFs are central to current steelmaking practices, where scrap and Direct Reduced Iron (DRI) produced in upstream ironmaking are melted under extreme thermal and chemical conditions. Refractory materials must remain dimensionally stable and chemically resistant in such settings, and our formulations are engineered to do exactly that. Our high-performance refractory systems support furnace stability, energy efficiency, and extended campaign life, helping bridge the transition between ironmaking and steelmaking in more sustainable production processes.

The following iron and steelmaking solutions can be applied to EAFs:

- MgO-C bricks and working linings: Dense refractory blocks made from magnesia and carbon that can be used in high-wear furnace zones such as sidewalls and slag lines to resist slag attack and thermal shock.

- Monolithic castables and repair mixes: Unshaped refractories that are applied to EAF walls and tapholes for quick gunning, shotcreting, and relining maintenance.

- Insulating and backfill systems: Lightweight refractory layers installed behind the working lining to limit heat loss and protect the furnace shell.

- Recycling technologies: Including collection, crushing, and reprocessing systems that recover spent refractories for use in new linings or slag conditioners, helping to reduce raw material waste and CO2 emissions.

Reheating Furnace

Reheating furnaces heat billets, blooms, and slabs to rolling temperatures exceeding 1200°C during iron and steelmaking. As these furnaces operate continuously at extreme heat, they require refractory linings that deliver strong insulation, uniform heat transfer, and reliable structural integrity over long service cycles. We have developed advanced refractory materials that are used in furnace linings and can deliver thermal efficiency, durability, and consistent performance throughout iron and steelmaking operations. These include Magmalox® and alumina-based refractories, fused-cast and sintered materials that offer outstanding corrosion resistance and thermal stability during cyclic heating. Magmalox®, in particular, enables steelmakers to refine control across all areas within the furnace, leading to significant improvement in furnace campaign life.

Speak to an expert

Contact Saint-Gobain Performance Ceramics & Refractories to discuss the right solution for your iron and steelmaking operations.