Steelmaking

Steelmaking processes operate under conditions that demand unwavering material performance. High temperatures, corrosive environments, and continuous thermal cycling place significant demands on every component involved. Refractory materials must not only endure these stresses but also contribute to consistent process stability over time. With expertise in refractory composition, thermal behaviour, and furnace refractory lining engineering, Saint-Gobain Performance Ceramics & Refractories develops products suited to the functional requirements of steelmaking operations. Each of our solutions is tailored to the different challenges in iron and steel production, supporting long-term process efficiency and equipment integrity.

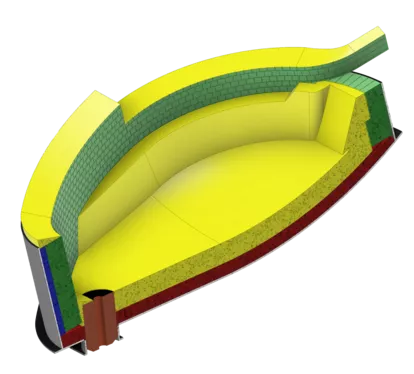

Electric Arc Furnace (EAF)

The Electric Arc Furnace (EAF) is an essential tool for reprocessing steel scrap, helping reduce the steel industry’s carbon footprint. This extremely aggressive process requires a large quantity of high-quality refractories.

Refractory materials are essential to electric arc furnace operation. They act as the containment system for liquid steel, reaching temperatures up to 1500°C. Protecting the vessel's integrity over time, refractories ensure resistance to corrosion, oxidation (atmosphere and burners), erosion (scrap charging) and thermal shock.

By using electricity, the electric arc furnace is a key process in this evolution toward less CO2 emission-intensive steelmaking processes. The temperatures reached in the electric arc furnace process exceed those needed for smelting standard steel, making electric arc furnaces suitable for processing alloy and stainless steel.

Bricks and monolithics from Saint-Gobain Performance Ceramics & Refractories are manufactured using carefully selected raw materials and stringently controlled processes to ensure resistance, quality, and safety.