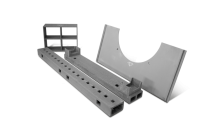

Trusted, reliable material technology delivers increased productivity and reduced energy consumption in the production of DPF & GPF filters, substrate manufacturing, sanitaryware, dinnerware and technical ceramics.

Customized design services are available, and Saint-Gobain Performance Ceramics & Refractories’ experienced engineers are on hand to support customers in selecting the most appropriate product and material for their applications. Unique designs and materials ensure high oxidation and corrosion resistance, excellent thermal shock resistance and outstanding structural support for kiln furniture systems.

Features and Benefits

- High oxidation

- High corrosion resistance

- Excellent thermal shock resistance

- Outstanding structural support

- Adapted mechanical strength

- Excellent creep resistance

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modolus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| Mulnorite® KN 176 | 82 | 1,700 | 2.7 | 17 | 10 | 5 | 5.3 |

| Mullfrax® EM 27 | 90 | 1,750 | 3 | 17 | 8 | 8 | 170 |

| Alundum® AH 191 A | 91 | 1,750 | 2.9 | 20 | 14 | 7 | 7 |

| AnnaCarbid® 42 | 40 | 1,430 | 2.5 | 20 | 20 | 10 | 5 |

| AnnaCarbid® 65 | 65 | 1,450 | 2.5 | 21 | 15 | 15 | 5 |

| AnnaCarbid® 94 | 84 | 1,500 | 2.5 | 17 | 20 | 20 | 5 |

| NSiC 2165 | 79 | 1,600 - 1,650 | 2.72 | 15 | 40 | 50 | 4.5 |

| NSiC 2172 | 80 | 1,600 | 2.65 | 17 | 35 | 45 | 4.5 |

| AnnaSicon® RTH | 75 | 1,650 | 2.63 | 17 | 40 | 35 | 4.5 |

| Silit® SK | 85 | 1,380 | 3 | 0 | 260 | 260 | 4.5 |

| Silit® SKD | 85 | 1,380 | 3 | 0 | 260 | 260 | 4.5 |

| N-Durance® | 70 | 1,450 | 2.75 | ≤ 1 | 170 - 180 | 170 - 190 | 4.4 |

| Crystar® 2000 | > 99 | 1,600 | 2.7 | 15 | 80 | 90 | 4.8 |

| Crystar® 3000 | > 97 | 1,600 | 2.7 | 15 | 80 | 90 | 4.8 |

| Hexoloy® | > 99 | 1,750 | 3.15 | < 2 | 380 | 370 | 4 |

Suitable for use in the production of DPF/GPF, sanitaryware, tableware and technical ceramics.

FAQ

Are standard support designs available?

Yes. Standard supports are available in frequently used dimensions. Saint-Gobain Performance Ceramics & Refractories’ experienced engineers are also on hand to recommend product and design options to optimize load, creep resistance, kiln atmosphere, and firing cycles.

Documents

Related Content

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

Diesel Particle Filters and Gas Particle Filters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of LO-MASS® kiln furniture - excellent strength, shape and assembly stability for large...

Sanitaryware and Dinnerware

Discover Saint-Gobain Performance Ceramics & Refractories’ sanitary and dinnerware solutions – advanced kiln furniture systems able to reduce energy...

Technical Ceramics Application

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of engineered ceramics and refractories – highly suited to producing high...

Related Product

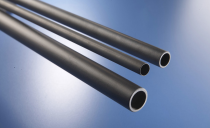

Silit® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Silit® silicon infiltrated rollers - optimal properties in a wide range of firing...

Hexoloy® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Hexoloy® silicon carbide rollers – ideal for use in high-temperature roller hearth...

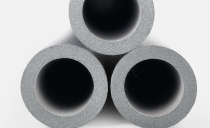

Crystar® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Crystar® recrystallized silicon carbide rollers – ideal for use in high-temperature...