Saint-Gobain Performance Ceramics & Refractories is recognized worldwide as the provider of choice for OEMs looking for robust products with long service lives.

Documents

Features and Benefits

Specifications

- Tried and tested material with narrow tolerances

- An ideal standard product for the first pass and the combustion area

Typical Chemical Analysis & Physical Properties

| Property | Value | Method | |

| Typical Chemical Analysis |

SiC Si3N4+ Others |

78% 17% 5% |

EN ISO 21068-2 EN 12698-2 DIN 51001 |

|

Maximum Application Temperature |

1,550ºC |

||

| Bulk Density | 2.65 kg/dm³ | EN 993-1 | |

| Apparent Porosity | 17 Vol.-% | EN 993-1 | |

| Cold Crushing Strenght | 140 MPa | EN 993-5 | |

| Modulus of Rapture at RT | 30 MPa | EN 993-6 | |

| Linear Thermal Expansion 250-400ºC 250-600ºC 250-800ºC 250-1,000ºC |

3.9 10-6/K |

EN 993-19 | |

| Thermal Conductivity at 400ºC at 800ºC at 1,000ºC |

18,4W/mK |

EN 993-15 | |

| Thermal Shock Resistance | 30 Cycles | DIN 51068-1 | |

| Steam Oxidation Resistance | 1,0% | ASTM C863 at 1,000°C/500h | |

Specifications

- Endowed, patented premium product for the most stringent requirements

- Suitable for all areas, particularly areas exposed to high wear and high stresses

- Ideal for use in repairs

Typical Chemical Analysis & Physical Properties

| Property | Value | Method | |

| Typical Chemical Analysis |

SiC Si3N4+ Others |

75% 22% 3.5% |

DIN EN ISO 21068-2 DIN 13925 DIN 13925 |

|

Maximum Application Temperature |

1,550ºC |

||

| For domestix waste incineration a maximum surface temperature | 1,150°C | ||

| Bulk Density | 2.70 kg/dm³ | EN 993-1 | |

| Apparent Porosity | 16 Vol.-% | EN 993-1 | |

| Cold Crushing Strength | 140 MPa | EN 993-5 | |

| Modulus of Rupture at RT | 40 MPa | EN 993-6 | |

| Linear Thermal Expansion 250-400ºC 250-600ºC 250-800ºC 250-1,000ºC |

3.9 10-6/K 3.9 10-6/K 4.0 10-6/K 4.6 10-6/K |

EN 993-19 | |

| Thermal Conductivity at 400ºC at 800ºC at 1,000ºC |

22W/mK 18W/mK 16W/mK |

EN 993-15 | |

| Thermal Shock Resistance | 30 Cycles | DIN 51068-1 | |

| Steam Oxidation at 1,000ºC / 500 h | 0.8% | ASTM C863 | |

Specifications

- Doped, patented, doubled fired material with glazed surface

- Suitable for all areas, particularly areas exposed to aggressive slags

Typical Chemical Analysis & Physical Properties

| Property | Value | Method | |

| Typical Chemical Analysis |

SiC Si3N4+ Others |

75% 21% 3.5% |

EN ISO 21068-2 DIN 12698-2 DIN 51001 |

|

Maximum Application Temperature |

1,550ºC |

||

| For domestic waste incineration a maximum surface temperature | 1,150°C | ||

| Bulk Density | 2.70 kg/dm³ | EN 993-1 | |

| Apparent Porosity | 12 Vol.-% | EN 993-1 | |

| Cold Crushing Strength | 140 MPa | EN 993-5 | |

| Modulus of Rupture at RT | 40 MPa | EN 993-6 | |

| Linear Thermal Expansion 250-400ºC 250-600ºC 250-800ºC 250-1,000ºC |

3.9 10-6/K 3.9 10-6/K 4.0 10-6/K 4.6 10-6/K |

EN 993-19 | |

| Thermal Conductivity at 400ºC at 800ºC at 1,000ºC |

33W/mK 21W/mK 18W/mK |

EN 993-15 | |

| Thermal Shock Resistance | 30 Cycles | DIN 51068-1 | |

| Steam Oxidation at 1,000ºC / 500 h | 0.4% | ASTM C863 | |

I can confirm once again that the Saint-Gobain T-Clip® PRO tile system in Refrax® TOP is extremely effective in protecting the combustion chamber tubewalls at our EfW in Portsmouth, Hampshire.

The first part installation was more than six years ago in 2016 and we have experienced no issues with the product. All subsequent system installations to fully protect the combustion chamber tubing has proven to be very stable, this was evident during the recent March ’23 24 monthly major outage. Linings in the boilers overall are in excellent condition and have contributed to us burning longer with extended periods between outages as previously noted.

Using T-Clip®PRO system in Refrax® TOP has proven very effective for us, protecting the tube wall and eliminating the regular large-scale repairs that were previously necessary when we had installed other products. I can highly recommend T-Clip® PRO system in Refrax® TOP and we are pleased to have Saint-Gobain as our material supply partner.

Gynn Beggs, Maintenance Manager

Veolia ES Hampshire Limited

Related Content

Waste to Energy Solutions with Silicon Carbide

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high performance refractory solutions for thermal waste treatment in waste to energy...

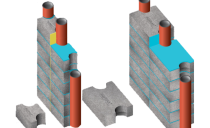

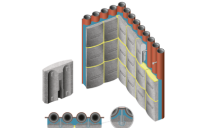

Back Cast SiC Tube Wall Tile Systems

Discover Saint-Gobain Performance Ceramics & Refractories’ T-Clip® range of tile systems. Simple self-leveling back castable products ensure optimum...

Mortar SiC Tube Wall Systems

Discover Saint-Gobain Performance Ceramics & Refractories’ traditional mortared tile system – simple, rapid replacement, even of individual wall tiles.

Custom Designed SiC Tube Wall: Tile or Brick

Saint-Gobain Performance Ceramics & Refractories offers a robust combination of experience and expertise in the manufacture of custom silicon carbide...

T-Clip® PRO Tile Systems in Refrax® Top Material

Challenge: The old system with potential for the heavy ash / slag build-up in upper levels falling could endangering personnel when they entered the boiler...

Related Products

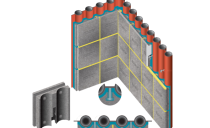

T-Clip® System

Discover Saint-Gobain Performance Ceramics & Refractories’ T-Clip® system - patented backfilling designed for reliable protection in all installation...

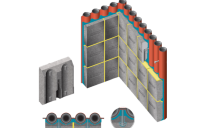

T-Clip® PRO System - Furnace Tube Protection

Discover Saint-Gobain Performance Ceramics & Refractories’ T-Clip® PRO - an optimized backfilled tile system offering maximum protection for vertical...

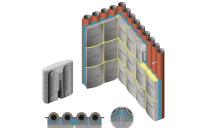

T-Clip® PROform System

Saint-Gobain Performance Ceramics & Refractories' T-Clip® PROform™ system a unique, patented tube protection system able to lower mean tile temperatures...

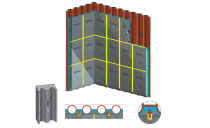

45° System

Discover Saint-Gobain Performance Ceramics & Refractories’ 45° mortared system, suitable for all installation systems.

Belly Brick System

Discover Saint-Gobain Performance Ceramics & Refractories’ belly brick system - straightforward protection for single tube walls with no metallic fixing...

Refrax® ProMor and PLUSflow - Mortar

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProMor and PLUSflow mortars - the backbone of its tile systems for waste to energy...

Refrax® ProCast - Castable

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProCast – a silicon carbide castable for waste to energy applications.

Refrax® ProGUN - Gunning

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProGUN range of gunning mixes for waste to energy applications.

Refrax® ProPlast - Plastic

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProPlast plastic mass for waste to energy applications.

Refrax® ProRam - Ramming

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProRam – a robust ramming mass for waste to energy applications.

Refrax® GT Max

The Refrax® family of nitride and oxynitride bonded silicon carbide materials utilize carefully selected raw materials with specific attention paid to...