Features and Benefits

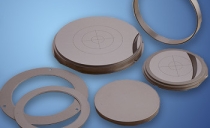

Saint Gobain SiSiC and NSiC products allow high precision, accuracy and speed in industrial metrology equipment, such as CMM and Positioning Equipment, due to their high specific stiffness, lightweight, low thermal expansion and high thermal conductivity. The unique combination of several key properties of silicon carbide makes it a superior choice to other materials, including alumina ceramic, aluminum, steel and granite. Key applications include CMM bridges and Z axis; guide rails and air-bearing stages.

Silicon carbide offers many advantages over traditional ceramic materials:

- Lightweight (~20% less)

- High specific stiffness (~25% higher)

- Low thermal expansion (~50% less)

- High thermal stability

| Properties | Unit | Value | ||

| Main Components |

SiC Si |

% % |

85 15 |

|

| Maximum Application Temperature1) | °C | 1380 | ||

| Bulk Density | EN 993-1 | kg/dm3 | 3.0 | |

| Apparent Porosity | EN 993-1 | Vol. % | 0 | |

| Young's Modulus | EN 843-2 | RT2) | GPa | 340 |

| Modulus of Rupture |

EN 993-6 EN 993-7 |

RT2) 1200°C |

MPa MPa |

260 260 |

| Coefficient of Thermal Expansion | EN 993-10 | α RT…1?300°C | 10-6/K | 4.5 |

| Thermal Conductivity | EN 993-15 | 1000°C | W/(m*K) | 35 |

1) Dependent on the corresponding operating conditions

2) Ambient temperature

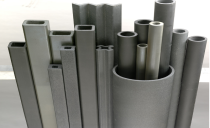

Below listed dimensions cover the majority of stardart sizes. Larger sizes and tighter tolerances on request.

| Dimensions | Tolerance X mm | Wall Thickness +1/-0,5 mm | Max Length ± 2 mm | |

| Height H ± X mm | Width B ± X mm | |||

| 20 | 20 | ± 1,0 | 6 | 2000 |

| 25 | 25 | ± 1,0 | 6 | 2000 |

| 30 | 20 | ± 1,0 | 6 | 2000 |

| 30 | 30 | ± 1,0 | 6 | 2000 |

| 35 | 35 | ± 1,0 | 6 | 2000 |

| 40 | 20 | ± 1,0 | 6 | 2000 |

| 40 | 25 | ± 1,0 | 6 | 2000 |

| 40 | 30 | ± 1,0 | 6 | 3000 |

| 40 | 40 | ± 1,0 | 6 | 3500 |

| 50 | 30 | ± 1,0 | 6 | 3500 |

| 50 | 40 | ± 1,0 | 6,3 | 3500 |

| 50 | 50 | ± 1.0 | 6,3 | 3500 |

| 60 | 40 | ± 1.2 | 6,8 | 3500 |

| 60 | 50 | ± 1.2 | 6,8 | 3500 |

| 60 | 60 | ± 1.2 | 7,3 | 3500 |

| 70 | 40 | ± 1.4 | 7,5 | 3500 |

| 70 | 50 | ± 1.4 | 7,5 | 3500 |

| 70 | 60 | ± 1.4 | 7,5 | 3500 |

| 80 | 40 | ± 1.4 | 8 | 3500 |

| 80 | 60 | ± 1.4 | 8,5 | 3500 |

| 80 | 80 | ± 1.4 | 9 | 3500 |

Related Industries

Aerospace

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics – designed for essential components in the aerospace industry.

Automotive and Electric Vehicles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of solutions for the automotive market.

Chemical

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics solutions for the chemical market.

Electronic & Measurement

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of engineered ceramics solutions for high precision measurement equipment.

Related Products

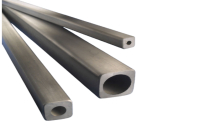

Beams

Discover Saint-Gobain Performance Ceramics and Refractories beams products family to provide structural support for numerous high temperature kiln and...

Silicon Carbide Beams

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of sintered silicon carbide beams.