Features and Benefits

- Patented dual refractory design

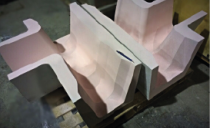

- Two-piece design (burner block and burner tube)

- Self-protecting silicon-oxynitride bond phase

- Thermal shock resistance

- Integrated semi-insulating backing layer

- Excellent oxidation resistance in the SiC hot face layer

- Less heat loss through the furnace shell

- Improved energy/fuel efficiency and operator comfort

- Fewer gas leaks

- Easier maintenance

FAQ

As Twinfrax® is comprised of two materials, is there an issue with differential thermal stress?

Twinfrax® has been designed with this specific issue in mind. The dual materials exhibit compatible thermal expansion coefficients meaning that high thermal stress is avoided.

What is the white layer present in Twinfrax® components?

Twinfrax® features a semi-insulating backing layer that reduces heat loss through the burner block. Its material composition is specifically designed for compatibility with the SiC hot face layer.

Documents

Related Content

Primary and Secondary Copper Furnaces

Refractory materials from Saint-Gobain Performance Ceramics & Refractories offer excellent performance and extended service life in the most critical...

Holding Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Launders

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractory solutions for molten metal transfer.

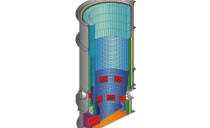

Shaft Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

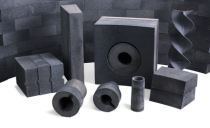

Related Products

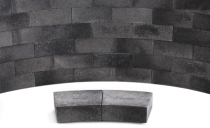

Hot Face Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of silicon carbide hot face bricks for copper furnaces.

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

Impact Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of impact bricks for the charging section of copper furnaces.

Back-up Safety Lining

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of backup safety linings for copper furnaces.

Firefrax CRM-30 and Carbofrax Series - Mortars

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of specialty mortars for copper furnaces.

Launder Hot Face

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of launders, troughs and tundish refractory components.