Specialty Ceramics

Structural Components for Kilns and Furnaces

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

Silicon Carbide Ceramics for Metrology

Components crafted from Advancer Nitride bonded Silicon Carbide, and Silit SK Siliconized Silicon Carbide provide the stiffness and thermal stability needed for high-precision measurement and motion systems. Their lightweight nature helps improve speed and accuracy in automation.

Metrology demands unparalleled precision to ensure processes are accurately measured and controlled. In industries where even minor errors are unacceptable, high-accuracy coordinate measuring machines (CMMs) and motion control systems depend on advanced materials to deliver reliable performance. At Saint-Gobain Refractories, we develop state-of-the-art ceramics engineered to enhance metrology systems’ accuracy, durability, and stability. Our materials empower your equipment to maintain peak performance and reliability, even under extreme operating conditions. By partnering with us, you gain access to innovative solutions that push the boundaries of precision and reliability in metrology applications.

Key Benefits of Ceramics for Metrology

The ceramic solutions from Saint-Gobain Refractories are engineered to meet the demanding requirements of metrology applications, delivering benefits that improve both accuracy and system performance:

- Thermal Stability for Accuracy: Our ceramics resist thermal expansion, ensuring consistent measurements even under changing temperatures.

- High Rigidity for Stability: Superior stiffness minimizes deformation, a critical feature for CMM and motion control systems to maintain precise positioning and alignment.

- Exceptional Durability: With excellent wear resistance, our materials reduce maintenance needs and ensure long-term operational reliability.

- Lightweight Efficiency: Lighter than metals but equally strong, our ceramics improve system responsiveness and reduce energy consumption in motion control applications.

These properties ensure that every measurement and movement meets the exacting standards required by advanced metrology equipment.

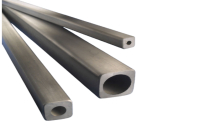

Material Description and Applications

We offer a range of specialty ceramics designed specifically for high-accuracy metrology and motion control equipment.

Silicon Carbide (SiC) Ceramics:

- Properties: Exceptional thermal stability, stiffness, and resistance to wear.

- Applications: Commonly utilized in CMM frames and structural components to maintain dimensional stability under stress and temperature fluctuations.

Want to Know More?

Precision doesn’t happen by chance. It is built with the right materials. Here at Saint-Gobain Refractories, we specialize in ceramics that empower CMMs and motion control equipment to achieve unparalleled accuracy and reliability. Contact our team today to learn how our advanced ceramics can elevate your metrology systems.

FAQ

Why are ceramics preferred over metals for metrology components?

The ceramics outperform metals with their superior thermal stability, higher stiffness, and resistance to wear, ensuring consistent accuracy and long-term reliability in demanding environments.

Can our ceramics be adapted for specialized designs?

Yes, our ceramics are tailored to meet the unique specifications of your equipment, ensuring optimal integration.

What types of motion control systems benefit from our materials?

Our ceramics are ideal for high-speed and high-precision motion control applications, including actuators and positioning systems.