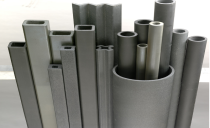

Beams can be manufactured in a wide range of cross-sections, wall thicknesses and lengths (up to 4 m) via slip-casting or extrusion processes.

As-fired beams can be used ‘as-is’ or these can be finished to meet a customer’s required tolerances.

Applications include structural support in high temperature processes and metrology equipment.

Features and Benefits

- Very high strength

- Oxidation resistance

- Thermal stability

- Low mass

- Structural support

- High precision metrology

Typical Properties of Hexoloy® SE SiC

| Properties | Unit | Value | ||

| Material | % | Hexoloy SE SiC | ||

| Maximum Use Temperature | °C | 1900 | ||

| Flexural Strength |

@ Room Temp @ 1,450°C @ 1,600°C |

MPa |

280 270 300 |

|

| Density | g/cc | 3.05 | ||

| Apparent Porosity | % | |||

| Modulus of Elasticity |

@ 20°C @ 1,300°C |

GPa |

420 363 |

|

| Coefficient of Thermal Expansion | 10-6/°C | 4.02 | ||

| Thermal Conductivity | @ 1,200°C | W/(mK) | 34.8 | |

Beams can be made in large selections of cross-sections, wall thickness and lengths (up to 4 m) using slip-casting or extrusion process.

Documents

Industries Served

Aerospace

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics – designed for essential components in the aerospace industry.

Automotive and Electric Vehicles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of solutions for the automotive market.

Chemical

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics solutions for the chemical market.

Electronics & Semiconductors

From pacemakers to pain suppression devices, our ceramics enable fabrication of critical electronic components for the medical, sensor, and consumer...

Related Products

Beams

Discover Saint-Gobain Performance Ceramics and Refractories beams products family to provide structural support for numerous high temperature kiln and...