Carbon Black Reactor Solutions

Specialized Refractory Materials for Carbon Black Reactors

The performance of a carbon black reactor is related to its refractory lining. High temperature reactors, designed to operate at temperatures >2,000°C, subject lining materials to extreme thermal, mechanical, and chemical stress as they convert feedstocks into high-quality carbon black. Saint-Gobain Performance Ceramics & Refractories have developed advanced lining solutions that combine high-performance alumina, zirconia and fused-cast materials along with dense and insulating castables to form robust linings that protect every zone of the carbon black reactor from erosion, corrosion, and heat loss. By aligning material composition and design with reactor temperature profiles and process conditions, these refractory systems promote stable operation, optimize thermal efficiency, and extend furnace campaigns.

Our proven lining materials include:

- Alundum® AH199 and AL100: High-purity alumina bricks offering excellent erosion resistance in the high-temperature combustion and reaction zones of carbon black reactors

- Mullfrax® 202 HF and AL102: Thermal-shock-resistant alumina materials designed to handle rapid cooling and heating in the quench and transition areas of the reactor

- Ziral™ and Zirnorite®: Zirconia-based bricks capable of withstanding temperatures up to 2,200°C in severe combustion zones, offering exceptional temperature resistance

- Jargal M fused-cast shapes: Erosion-resistant fused cast materials ideally suited for the choke and inlet sections of carbon black reactors, where gas and velocity and particle abrasion are at their highest.

- Supcast® / CA334 and RI34HR / CA333 castables: Dense and insulating alumina castables used in the backup layers of carbon black reactor linings to improve thermal insulation, mechanical strength, and overall energy efficiency.

Tailored Engineering for Reactor Optimization

Since carbon black reactors differ in geometry, temperature gradients, and gas flow they require refractory systems that perform reliably regardless of where they are installed within the reactor. We offer customized linings that align with each client’s operating profile, temperature range, and feedstock chemistry. With the application of advanced thermal modeling and shape design our refractory linings can enhance reactor temperature uniformity, support consistent process conditions, and extend maintenance intervals for improved operational reliability.

Reactor Applications

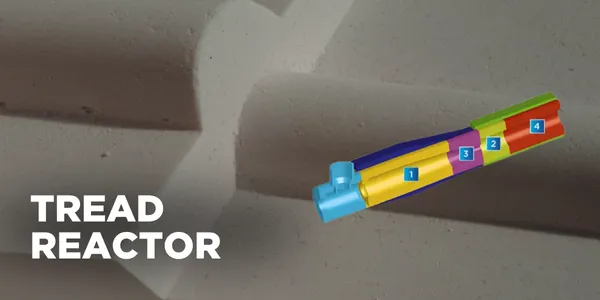

Our carbon black reactor solutions are designed for both tread and carcass reactors, where precise temperature control and material durability are essential:

- Tread reactors: Ziral™, Zirnorite®, and Jargal M can be used in combustion and choke zones in carbon black reactors to resist erosion and thermal shock, ensuring consistent temperature control and preserving mechanical strength for extended lining life.

- Carcass reactors: Mullfrax® 202 HF, AL102, and Alundum® AH199 provide thermal shock resistance and durability in reaction and quench zones, while backup layers made with Supcast® and RI34HR castables enhance insulation, reduce heat loss, and maintain structural stability throughout reactor operation.

Integrating these materials can help manufacturers achieve higher yield, lower energy consumption, and stable, efficient operation throughout carbon black processing.