Negro de Fumo

A Saint-Gobain Performance Ceramics & Refractories tem sido um fornecedor líder de revestimentos refratários completos para reatores de Negro de Fumo por mais de três décadas.

Uma gama de soluções projetadas sob medida está disponível para as camadas de face quente e de backup em reatores de rodagem e carcaça. Estes incluem:

- Tijolos e formas de cromo-alumina queimados ou pré-moldados

- Tijolos de alumina de alta pureza nas classes AH199, AL100 e Alfrax101

- Tijolos Mullfrax® e AL102 resistentes ao dano por choque térmico

- Zirnorite® tijolos à base de Zircônia para uso em temperatura mais alta

- Peças fundidas em Jargal M para resistência máxima à erosão

- Concretos Isolantes e densos para camadas de backup

Soluções para reatores

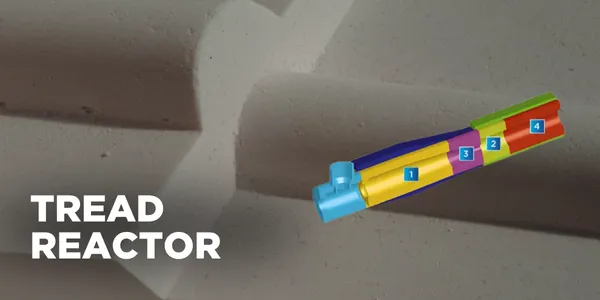

Clique em Reator da rodagem para saber mais:

Tailored Engineering for Reactor Optimization

Since carbon black reactors differ in geometry, temperature gradients, and gas flow they require refractory systems that perform reliably regardless of where they are installed within the reactor. We offer customized linings that align with each client’s operating profile, temperature range, and feedstock chemistry. With the application of advanced thermal modeling and shape design our refractory linings can enhance reactor temperature uniformity, support consistent process conditions, and extend maintenance intervals for improved operational reliability.

Reactor Applications

Our carbon black reactor solutions are designed for both tread and carcass reactors, where precise temperature control and material durability are essential:

- Tread reactors: Ziral™, Zirnorite®, and Jargal M can be used in combustion and choke zones in carbon black reactors to resist erosion and thermal shock, ensuring consistent temperature control and preserving mechanical strength for extended lining life.

- Carcass reactors: Mullfrax® 202 HF, AL102, and Alundum® AH199 provide thermal shock resistance and durability in reaction and quench zones, while backup layers made with Supcast® and RI34HR castables enhance insulation, reduce heat loss, and maintain structural stability throughout reactor operation.

Integrating these materials can help manufacturers achieve higher yield, lower energy consumption, and stable, efficient operation throughout carbon black processing.