Sistemas para fornos

Os produtos e soluções da Saint-Gobain Performance Ceramics & Refractories para estufas e fornos são projetados e desenvolvidos especificamente para facilitar um desempenho consistente e a longo prazo a altas temperaturas (até 1,800 ° C) e sob condições severas de operação.

Estão disponíveis soluções para todos os tipos comuns de fornos em uma ampla gama de indústrias.

Solução por aplicações

Clique em suas aplicações para saber mais:

Catodos Em Pó De Baterias De Íons De Lítio

Key Benefits of Our Saggers and Rollers

- Extended Service Life

- Increased CAM Capacity

- Reduced Ceramic Waste

- Increased Energy Efficiency

- High wear, corrosion, and chemical resistance

- Robust mechanical strength

- High product quality and reliability

- Increased service temperatures that reach 1,380°C

- Improved corrosion, chemical, and oxidation resistance

- Maximized mechanical strength

- Long service life

- Increased service temperatures that approach 1,750°C

Material Description and Applications

Versatile Use in RHKs: Hexoloy® and Silit® rollers, along with our saggers, are integral to the operation of roller hearth kilns. These kilns produce a wide range of products, including electronic components and lithium-ion battery materials like cathode active material (CAM). Rollers transport saggers through different kiln zones, ensuring consistent heating and efficient material processing.

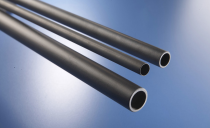

Silicon Carbide Rollers: Our rollers, made from high-quality silicon carbide (SiC), are engineered to endure the cyclical loading of saggers at elevated temperatures in corrosive environments. These rollers are designed to meet the stringent demands of roller hearth kiln (RHK) operators, ensuring maximum roller lifespan and minimal deflection. Improper material selection or construction can lead to roller failure and sagger misalignment, causing damage and increased kiln downtime.

Preferred Roller Materials: Silit® SK and Hexoloy® SE rollers from Saint-Gobain Performance Ceramics & Refractories are the top choices for RHKs due to their superior performance and reliability. These rollers can be specified for new kilns, or our engineering team can assist in selecting and supplying replacement rollers for existing kilns.

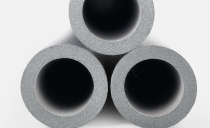

High-Performance Saggers: Saggers are essential for containing and conveying products through the rapid heating, high-temperature, and corrosive zones of RHKs. Properly designed saggers maintain structural integrity, resist chemical corrosion from lithium precursor species, and optimize thermal transport to the powder.

PowerCeram™ Saggers: Our next-generation PowerCeram™ saggers, made from advanced silicon carbide, enhance kiln capacity, reduce energy consumption, and extend sagger lifecycle. These saggers are customizable to meet specific heat treatment challenges and come in various shapes and sizes to suit different process conditions.

Contact Us for More Information

Optimize Your Kiln Performance: To maintain the efficiency of your roller hearth kilns and ensure the effective production of lithium-ion battery cathode powders, contact Saint-Gobain Performance Ceramics & Refractories. Our team can help you choose the best equipment for your specific needs.

Perguntas frequentes

What are saggers and rollers used for in roller hearth kilns?

Saggers in roller hearth kilns serve as containers for powder materials, protecting against contamination and ensuring proper sintering. Rollers are used to transport the saggers within the kiln.

What benefits do rollers and saggers offer in producing lithium-ion battery cathode powders?

Saggers and rollers enhance control over the conditions necessary for efficient calcination and sintering. Saggers contain the powders during high-temperature processes, while rollers ensure consistent transportation of the saggers.

What materials are used to create saggers and rollers at Saint-Gobain Refractories?

Saint-Gobain Refractories uses materials such as silicon carbide, Alundum®, Annamullit®, and Mullfrax® for saggers. For rollers, materials include Hexoloy® SE, Silit® SK, and Crystar®. Explore our brochures for more details on our material offerings.

Documentos

Sistemas Cerâmicos Rolos Cerâmicos para Veículos Elétricos

As baterias de íons de lítio são onipresentes em veículos elétricos e armazenamento, eletrônicos portáteis, equipamentos médicos, ferramentas elétricas e

Fornos e Fornos de Sistemas Cerâmicos - Automotivo

Os produtos e soluções para fornos e fornalhas da Saint-Gobain Ceramic Systems são concebidos e desenvolvidos para muitas aplicações, a fim de facilitar um

Sistemas Cerâmicos para Fornos e Fornos

Os produtos e soluções para fornos e fornalhas da Saint-Gobain Ceramic Systems são concebidos e desenvolvidos para muitas aplicações, a fim de facilitar um