Negro de Fumo

A Saint-Gobain Performance Ceramics & Refractories tem sido um fornecedor líder de revestimentos refratários completos para reatores de Negro de Fumo por mais de três décadas.

Uma gama de soluções projetadas sob medida está disponível para as camadas de face quente e de backup em reatores de rodagem e carcaça. Estes incluem:

- Tijolos e formas de cromo-alumina queimados ou pré-moldados

- Tijolos de alumina de alta pureza nas classes AH199, AL100 e Alfrax101

- Tijolos Mullfrax® e AL102 resistentes ao dano por choque térmico

- Zirnorite® tijolos à base de Zircônia para uso em temperatura mais alta

- Peças fundidas em Jargal M para resistência máxima à erosão

- Concretos Isolantes e densos para camadas de backup

Soluções para reatores

Clique no seu equipamento para saber mais:

- Da rodagem

Da rodagem

A Saint-Gobain Performance Ceramics & Refractories é um fornecedor global de soluções refratárias, especializada em todas as principais tecnologias de Negro de Fumo.

O processo de comissionamento começa com o operador do forno especificando as condições operacionais necessárias para produzir o grau de negro de fumo desejado.

Fatores como tecnologia de reatores, temperatura, geometria, fonte de combustível e fonte de alimentação determinarão a solução oferecida.

As condições de operação variam de acordo com a zona do forno, com diferentes zonas apresentando desafios específicos em termos de atmosfera (oxidação ou redução), velocidades do gás, interações químicas e flutuações de temperatura (dano por choque térmico).

A Saint-Gobain Performance Ceramics & Refractories trabalha em estreita colaboração com os operadores do forno para fornecer soluções refratárias que atendam às metas de desempenho e custo do operador. As soluções de revestimento também são personalizadas por forma e grau de material.

Reactor Structure and Operation

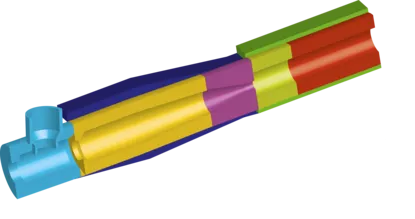

Carbon black tread reactors typically consist of several critical zones, each playing a distinct role in the production process:

1. Combustion Chamber: The initial stage where fuel combustion occurs at extremely high temperatures to generate the thermal energy needed for carbon black formation.

2. Reaction Zone: The main area where the formation of carbon black takes place through the interaction of feedstock with high-temperature gases.

3. Choke: A narrow section that helps regulate the reaction flow and maintain the necessary conditions for efficient carbon black production.

4. Quench Zone: This zone rapidly cools the reaction mixture to halt further carbon black formation and stabilize the final product.

These reactors often operate at temperatures exceeding 1500°C (2732°F) in certain zones, subjecting the reactor lining to highly erosive and corrosive environments due to the presence of hot gases and particulates.

Operating Conditions

The operating conditions of a carbon black tread reactor vary across different zones, each presenting unique challenges such as varying atmospheres (oxidizing or reducing), high gas velocities, intense chemical interactions, and frequent temperature fluctuations. Each of these factors influences the choice of refractory material and design.

Refractory Solutions

Saint-Gobain offers customized refractory solutions tailored to the specific needs of each reactor zone

- Hot Face: Uses 99% alumina bricks (AL 100, AH 199H) or zirconia bricks (ZH192) to provide resistance to high temperatures and thermal shock.

- Backup Layer: Bubble alumina castable (RI34/CA333) for insulation and additional protection.

- Hot Face: 99% alumina bricks (AL 100, AH 199) or 90% alumina bricks (Mullfrax® 202 HF) for durability against high temperatures and erosion.

- Backup Layer: Bubble alumina castable (RI34/CA333) or dense alumina castable (Supcast/CA334) for added thermal insulation and structural support.

- Hot Face: Uses high alumina bricks (AL 100, AH 199 H), Monocriram, or fused cast alumina (Jargal M) for extreme wear resistance.

- Backup Layer: Bubble alumina castable (RI34HR/CA333) to further protect against intense conditions.

- Hot Face: 90% alumina bricks (Mullfrax® 202 HF, MSR2) or high alumina bricks (AL 102 / AL102 V) to withstand rapid cooling and thermal shock.

- Backup Layer: Bubble alumina castable (RI34HR/CA333) or dense alumina castable (Supcast/CA334) for extra resilience.

Key Benefits of Advanced Refractory Solutions

- Extended Reactor Lifetime: Using advanced refractory materials can significantly extend the lifespan of carbon black tread reactors, reducing the frequency of relining and associated downtime.

- Reduced Maintenance Requirements: Enhanced durability leads to less frequent maintenance, which reduces operational costs and interruptions.

- Improved Resistance to Erosion and Corrosion: High-quality refractory materials are specifically engineered to resist the erosive and corrosive effects of hot gases and particulates.

- Enhanced Thermal Shock Resistance: The ability to withstand rapid temperature fluctuations minimizes the risk of thermal damage and ensures consistent performance.

- Increased Operational Efficiency: Optimal refractory solutions contribute to stable operating conditions, improving overall process efficiency and ensuring consistent product quality.

Carbon Black Technologies Solutions

Selecting the right refractory material is critical for the optimal performance of carbon black tread reactors. High-purity alumina and zirconia-based products are preferred for their excellent resistance to extreme temperatures, erosion, and corrosive environments. The specific grade and form of these materials (such as bricks, shapes, or castables) are chosen based on the requirements of each reactor zone and the unique challenges it presents.

By utilizing these advanced refractory solutions, carbon black manufacturers can achieve longer operational campaigns, enhance product quality, and boost overall efficiency in their tread reactors.

Saint-Gobain Performance Ceramics & Refractories works closely with furnace operators to develop and deliver refractory solutions that meet both performance and economic goals. These lining solutions are customized in terms of material form and grade to address the specific needs of each reactor zone and to optimize reactor performance.

Documentos

Negro de Fumo

SOLUÇÕES PARA REATORES DE CARCAÇA E PISTA