Sistemas para fornos

Os produtos e soluções da Saint-Gobain Performance Ceramics & Refractories para estufas e fornos são projetados e desenvolvidos especificamente para facilitar um desempenho consistente e a longo prazo a altas temperaturas (até 1,800 ° C) e sob condições severas de operação.

Estão disponíveis soluções para todos os tipos comuns de fornos em uma ampla gama de indústrias.

Solução por aplicações

Clique em suas aplicações para saber mais:

SOFC-Produção

| Nossa Lo-Massa® Os sistemas de móveis ultra-forno para queima de louças, porcelanas e louças sanitárias incluem placas de 4 mm de espessura e fixadores de placas para montagens avançadas de móveis de forno. Eles permitem carga de alta capacidade em operações industriais automatizadas. Usado em fornos em lote e em túnel até 1,500°C.

Com a nossa Lo-Mass® Sistemas de móveis ultra-fornos, somos capazes de fornecer aos nossos clientes soluções tangíveis para economizar energia significativamente e reduzir CO2 emissões. Nossa Lo-Massa® Os sistemas de móveis ultra-forno permitem que nossos clientes aumentem a produtividade enquanto processam em um ambiente mais sustentável e “mais verde”. Nossos produtos e sistemas são projetados para melhorar a relação produto/móveis do forno, permitindo o carregamento ideal do produto e a eficiência geral da queima. |

|

|

|

|

| Economia de energia e CO2 redução | Redução de peso | Aumento da produtividade | Ciclos de aquecimento e resfriamento mais rápidos |

Key Benefits of Lo-Mass® Ultra Kiln Furniture Systems

- Enhanced stacking density

- Lower energy consumption

- Decreased CO2 emissions

- Improved productivity (>33%)

- Increased lifespan of ceramics (>25%)

- Weight mass reduction

- Quicker heating and cooling cycles

- Better product-to-kiln furniture ratio to achieve efficient firing

Material Description and Applications

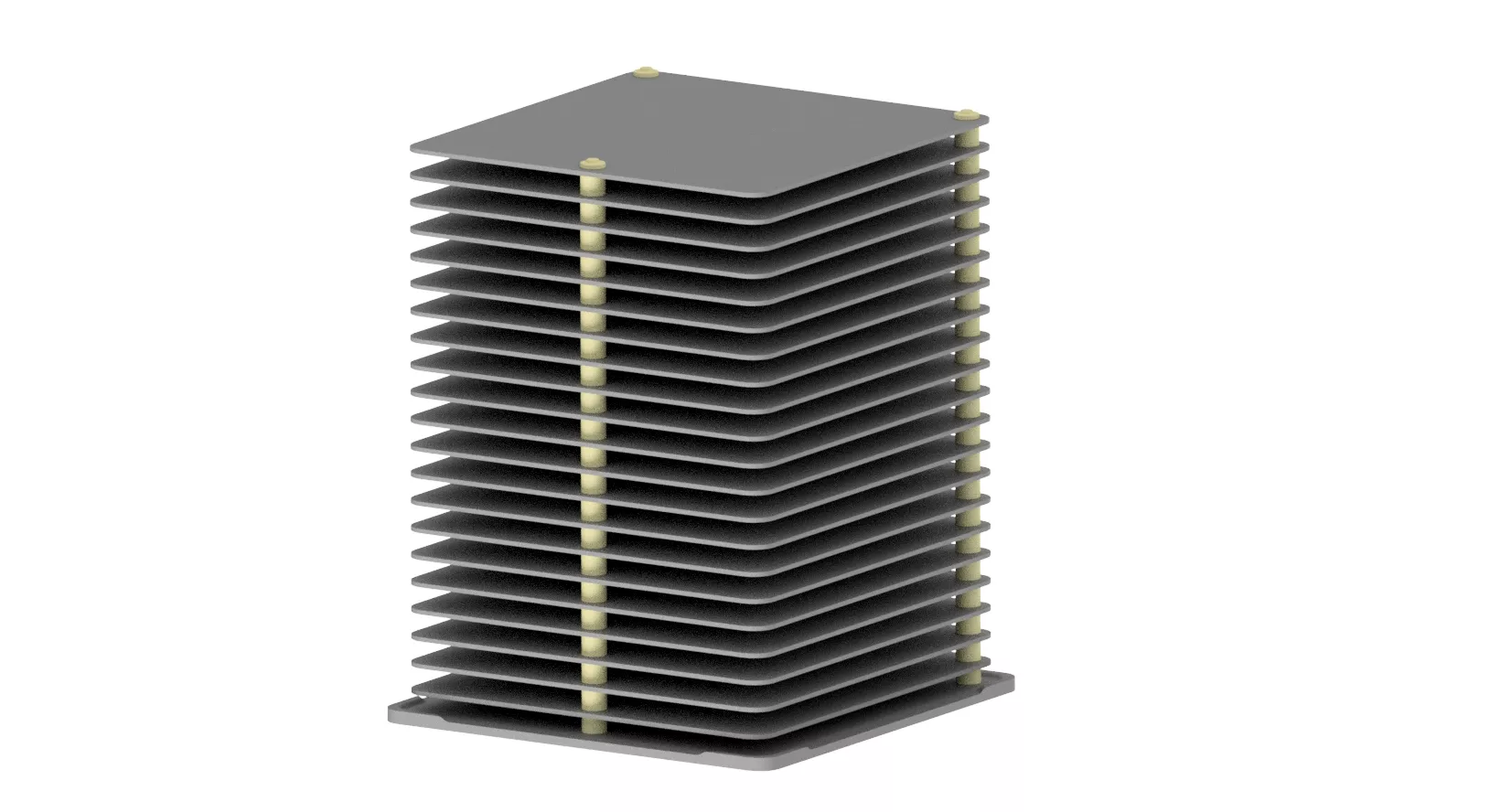

SOFC production and SOEC production rely on kiln furniture systems, as they can position and move ceramic components as they undergo firing processes. Ceramic substrates act as a foundation for essential components, like electrodes, as well as the electrolyte. The substrates ensure the longevity and efficiency of the SOECs and SOFCS. They make sure the SOECs and SOFCs have specific attributes, including thermal stability, ionic conductivity, and mechanical strength.

Our Lo-Mass® Ultra kiln furniture systems for SOFC and SOE applications include 4 mm thick slabs and stacking supports for assemblies. They allow for increased firing capacity and automated industrial operations. Used in both batch and tunnel kiln firing up to 1,500°C, this kiln furniture solution offers an improved lifetime and reduces product replacements.

Through our Lo-Mass® Ultra kiln furniture systems, we can provide a tangible solution to the challenge of firing energy versus CO2 emissions–which is linked to kiln furniture weight. Our Lo-Mass® Ultra kiln furniture systems enable customers to use SiC plates for SOFC and SOE substrate firing, and to upgrade their product quality e.g. optimized substrate flatness while processing in a more sustainable and “greener” environment.

Our products and systems can be designed based on our customers' needs. We clearly target improving the product-to-kiln furniture ratio, allowing optimal product loading and overall firing efficiency with superior product quality.

Our Lo-Mass® Ultra kiln furniture systems are extremely useful for SOFC and SOEC production, helping to lower the amount of firing time required and improving energy efficiency. Imbued with a lightweight design, Lo-Mass Ultra® kiln furniture systems can reduce heat storage. They do not need as much energy to heat up a kiln, and can still deliver a uniform temperature, therefore these furniture systems have the capability to deliver quality ceramic components with specific attributes.

Want to know more?

By using our Lo-Mass® Ultra kiln furniture systems for solid oxide electrolyzer cell and solid oxide fuel cell production, you’re investing in sustainability and efficiency. Visit our website now and speak with our experts to see whether our Lo-Mass® Ultra kiln furniture could be of use to you.

FAQ

What are SOECs and SOFCs?

Solid oxide electrolyzer cells (SOECs) and solid oxide fuel cells (SOFCs) are both versions of solid oxide electrochemical cells which function at increased temperatures. These cells can be used to produce clean energy systems. SOECs utilize electricity to generate fuel from water, while SOFCs are able to produce electrical energy through transforming chemical energy from fuel.

How do silicon carbide kiln furniture systems enhance productivity?

Our own kiln furniture systems incorporate silicon carbide because it can help enhance the productivity of ceramic manufacturing procedures. They can resist high temperatures and offer better thermal efficiency. Moreover, silicon carbide has good durability, therefore its service life will likely be increased as a result.

Are there any environmental benefits to using Lo-Mass® Ultra kiln furniture systems?

Sustainability lies at the heart of our products. Our Lo-Mass® Ultra kiln furniture systems produce less CO2 emissions and consume less energy during use. At the same time, these systems are also able to be extremely productive and form products that will meet all your expectations.

Documentos

Lo-Mass® Ultra Automotivo

Na Saint-Gobain, o nosso compromisso com a sustentabilidade permite-nos desenvolver soluções inovadoras e económicas que respondem ao desafio de proteger o

Sistemas Cerâmicos para Fornos e Fornos

Os produtos e soluções para fornos e fornalhas da Saint-Gobain Ceramic Systems são concebidos e desenvolvidos para muitas aplicações, a fim de facilitar um