Systèmes pour fours

Les produits et solutions Saint-Gobain Performance Ceramics & Refractories sont spécifiquement conçus et développés pour permettre des performances constantes, durables à des températures élevées (jusqu'à 1,800°C) et dans des conditions d'utilisation très sévères.

Des solutions sont disponibles pour tout type de fours dans un large éventail d'industries.

Solution par application

Cliquez sur votre application pour en savoir plus :

Production SOFC

|

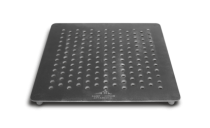

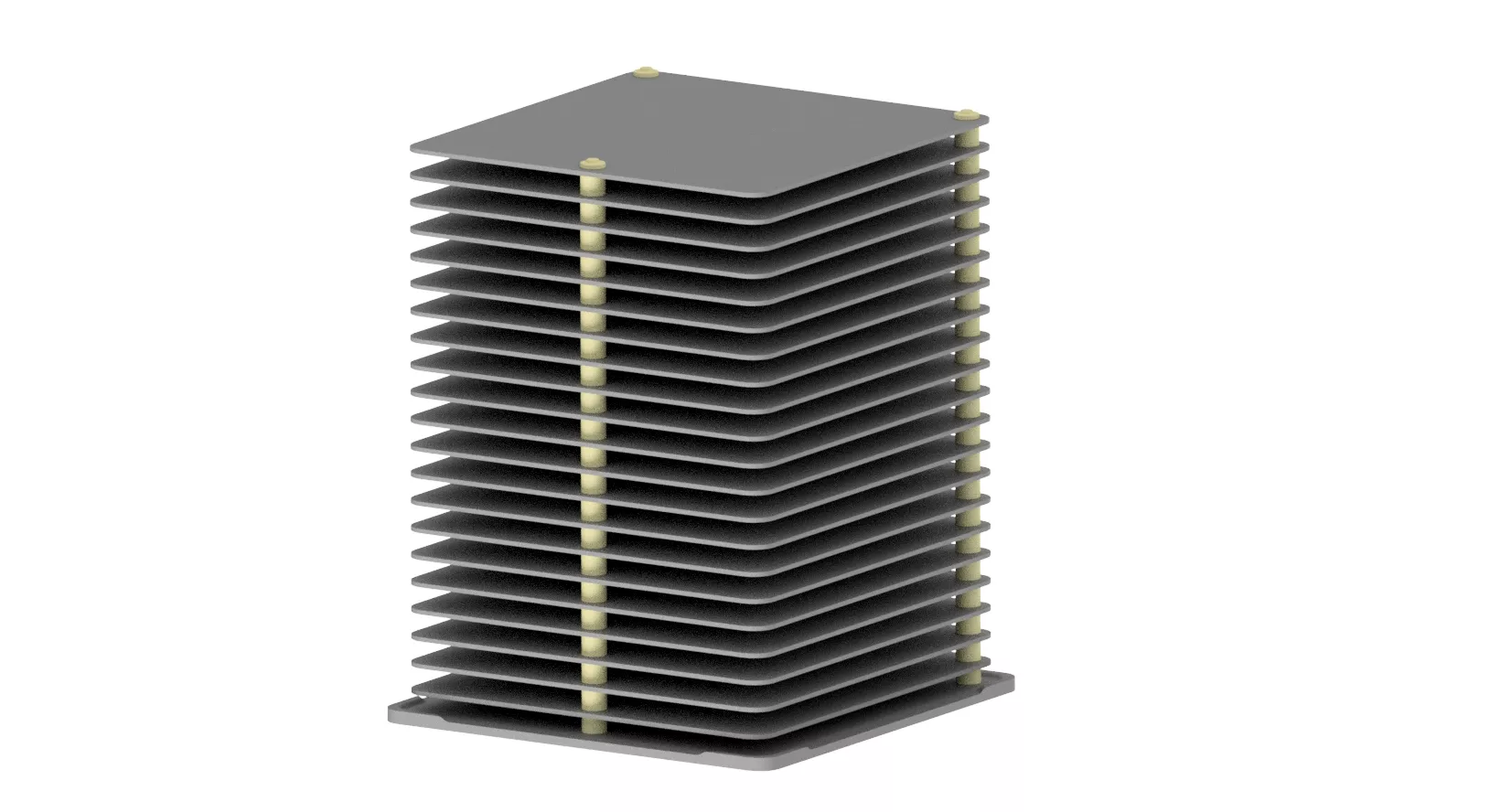

Notre Lo-Mass® systèmes de meubles de four Ultra pour la cuisson de vaisselle, de porcelaine et de produits sanitaires comprennent des plaques de 4 mm d'épaisseur et des poseurs de plaques pour des assemblages de meubles de four avancés. Ils permettent un chargement de grande capacité dans les opérations industrielles automatisées. Utilisé dans les fours discontinus et tunnels jusqu'à 1,500 XNUMX °C.

Avec notre Lo-Mass® Systèmes de supports de cuisson ultra, nous sommes en mesure d'apporter à nos clients des solutions concrètes pour économiser considérablement l'énergie et réduire les émissions de CO2 émissions. Notre Lo-Mass® Les systèmes de meubles de cuisson Ultra permettent à nos clients d'augmenter leur productivité tout en traitant dans un environnement plus durable et plus «vert». Nos produits et systèmes sont conçus pour améliorer le rapport produit/support de four permettant un chargement optimal du produit et une efficacité de cuisson globale. |

|

|

|

|

| Économies d'énergie et CO2 réduction | Réduction de la masse pondérale | Augmentation de la productivité | Cycles de chauffage et de refroidissement plus rapides |

Key Benefits of Lo-Mass® Ultra Kiln Furniture Systems

- Enhanced stacking density

- Lower energy consumption

- Decreased CO2 emissions

- Improved productivity (>33%)

- Increased lifespan of ceramics (>25%)

- Weight mass reduction

- Quicker heating and cooling cycles

- Better product-to-kiln furniture ratio to achieve efficient firing

Material Description and Applications

SOFC production and SOEC production rely on kiln furniture systems, as they can position and move ceramic components as they undergo firing processes. Ceramic substrates act as a foundation for essential components, like electrodes, as well as the electrolyte. The substrates ensure the longevity and efficiency of the SOECs and SOFCS. They make sure the SOECs and SOFCs have specific attributes, including thermal stability, ionic conductivity, and mechanical strength.

Our Lo-Mass® Ultra kiln furniture systems for SOFC and SOE applications include 4 mm thick slabs and stacking supports for assemblies. They allow for increased firing capacity and automated industrial operations. Used in both batch and tunnel kiln firing up to 1,500°C, this kiln furniture solution offers an improved lifetime and reduces product replacements.

Through our Lo-Mass® Ultra kiln furniture systems, we can provide a tangible solution to the challenge of firing energy versus CO2 emissions–which is linked to kiln furniture weight. Our Lo-Mass® Ultra kiln furniture systems enable customers to use SiC plates for SOFC and SOE substrate firing, and to upgrade their product quality e.g. optimized substrate flatness while processing in a more sustainable and “greener” environment.

Our products and systems can be designed based on our customers' needs. We clearly target improving the product-to-kiln furniture ratio, allowing optimal product loading and overall firing efficiency with superior product quality.

Our Lo-Mass® Ultra kiln furniture systems are extremely useful for SOFC and SOEC production, helping to lower the amount of firing time required and improving energy efficiency. Imbued with a lightweight design, Lo-Mass Ultra® kiln furniture systems can reduce heat storage. They do not need as much energy to heat up a kiln, and can still deliver a uniform temperature, therefore these furniture systems have the capability to deliver quality ceramic components with specific attributes.

Want to know more?

By using our Lo-Mass® Ultra kiln furniture systems for solid oxide electrolyzer cell and solid oxide fuel cell production, you’re investing in sustainability and efficiency. Visit our website now and speak with our experts to see whether our Lo-Mass® Ultra kiln furniture could be of use to you.

FAQ

What are SOECs and SOFCs?

Solid oxide electrolyzer cells (SOECs) and solid oxide fuel cells (SOFCs) are both versions of solid oxide electrochemical cells which function at increased temperatures. These cells can be used to produce clean energy systems. SOECs utilize electricity to generate fuel from water, while SOFCs are able to produce electrical energy through transforming chemical energy from fuel.

How do silicon carbide kiln furniture systems enhance productivity?

Our own kiln furniture systems incorporate silicon carbide because it can help enhance the productivity of ceramic manufacturing procedures. They can resist high temperatures and offer better thermal efficiency. Moreover, silicon carbide has good durability, therefore its service life will likely be increased as a result.

Are there any environmental benefits to using Lo-Mass® Ultra kiln furniture systems?

Sustainability lies at the heart of our products. Our Lo-Mass® Ultra kiln furniture systems produce less CO2 emissions and consume less energy during use. At the same time, these systems are also able to be extremely productive and form products that will meet all your expectations.

Documents

Ceramic-Systems-LO-MASS®-Ultra-plates-Fuel Cells-EN-A4-web

At Saint-Gobain, our commitment to sustainability enables us to develop innovative, cost effective solutions that meet the challenge of protecting the

Ceramics-Systems-for-Kilns-&-Furnaces-EN-A4-web

The products and solutions for kilns & furnaces under Saint-Gobain Ceramic Systems are designed and developed for many applications to facilitate