Petrochemistry, Syngas and Hydrogen

Saint-Gobain Performance Ceramics & Refractories delivers high-performance ceramic linings and components tailored for the petrochemical industry. Our advanced materials are designed to withstand the toughest conditions, ensuring maximum durability and reliability in demanding petrochemical applications.

We combine cutting-edge technology with innovative designs to create solutions that not only enhance performance but also reduce environmental impact. Our products are engineered for longevity, offering superior resistance to erosion, corrosion, and mechanical stress, ensuring long-lasting results in the harshest environments.

With a dedicated team of application specialists, R&D experts, and production professionals, we focus on providing custom-engineered solutions that add value at every stage. Using high-purity materials and precise manufacturing techniques, we create shapes and components suited to a wide range of petrochemical applications.

At Saint-Gobain, we are committed to building long-term partnerships. We look forward to collaborating with you to identify opportunities for process optimization and provide tailored solutions that elevate your operations.

Solution By Petrochemical Technologies

Click on your equipment to find more:

- Gasifiers

- Secondary Reformers

Secondary Reformer Alumina Refractories

Global demand for efficient syngas production is driving innovations in refractory materials designed to withstand the extreme conditions of secondary reformers.

Saint-Gobain Performance Ceramics & Refractories is at the forefront of this evolution. We offer a comprehensive portfolio of high-performance alumina refractories engineered to deliver superior performance in the high-temperature, high-hydrogen environments typical of reforming processes.

Material Overview and Applications

- Increased Yield: Optimize production efficiency with refractory materials designed to enhance throughput.

- Reduced Shutdown: Minimize downtime with durable materials that extend the operational life of your reformers.

- Increased Reliability: Ensure consistent performance with refractory solutions that resist erosion, corrosion, and thermal shock.

Saint-Gobain’s alumina refractory products are specifically engineered to meet the rigorous demands of secondary reformers. These materials are proven to perform in the challenging conditions of high temperatures and elevated hydrogen presence characteristic of the reforming process.

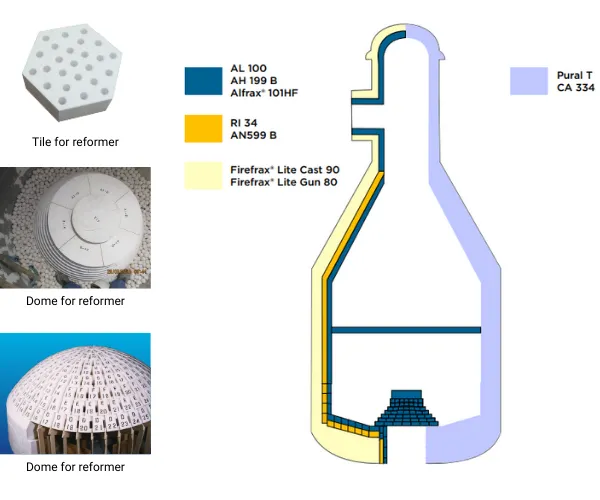

The product range includes various complex shapes, such as dome structures, target tiles, and sidewall shapes, all manufactured with the highest dimensional tolerances and consistent material properties. Saint-Gobain also provides essential backup insulating layers behind these shapes, ensuring comprehensive protection and performance. For operations requiring a lining composed entirely of monolithic refractories, Saint-Gobain offers high-purity options that deliver robust protection in the most demanding environments.

Secondary reformers operate under severe conditions that demand robust refractory solutions. Saint-Gobain’s alumina products are ideally suited for these applications, offering unparalleled durability and performance. Our materials are designed to withstand the high temperatures and reactive environments of syngas production, ensuring the longevity and reliability of your reformer linings. With decades of experience, we have refined our manufacturing processes to deliver refractory solutions that meet the highest standards of dimensional accuracy and material consistency.

Whether your operations involve complex dome shapes, sidewalls, or backup insulation layers, Saint-Gobain’s range of alumina refractories provides the comprehensive solutions you need to maintain peak efficiency and safety in your syngas production processes.

FAQ

Can Saint-Gobain provide backup insulation layers?

Yes, we provide high-quality backup insulating layers to complement our refractory shapes, ensuring comprehensive lining solutions.

How do Saint-Gobain's alumina refractories perform in high-temperature, high-hydrogen environments?

Our alumina refractories are engineered for maximum erosion and corrosion resistance, ensuring long service life even under the most challenging conditions.

What shapes and configurations are available?

We offer a wide range of complex shapes, including dome structures, target tiles, and sidewall shapes, all manufactured to precise dimensional tolerances for reliable performance.

Want to Know More?

Contact our team of experts to discover how Saint-Gobain's alumina refractories can enhance the performance of your secondary reformers. Click the button below to get in touch and explore our tailored solutions.