Ironmaking

General Areas Served

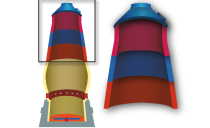

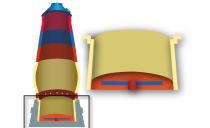

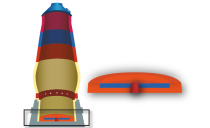

Blast furnace

Challenging conditions affect every area of a conventional blast furnace. For the hearth pad and hearth wall, tuyere belt, bosh and belly, lower and upper stack the lining of these areas has to deal with elements such as molten iron, corrosive vapors and abrasion from the solid burden. Raw materials entering through the throat may be a source of wear and tear, while coarse particles and carbon monoxide-rich gases produced as by-products can cause problems from the bottom up.

At Saint-Gobain Performance Ceramics & Refractories, we develop advanced, sustainable solutions for every stage of ironmaking. Our Coranit® Al and SlagR ceramic cup technology reduces CO₂ emissions and extends furnace life. We offer castable and shotcrete options for various furnace repairs, including the hearth and stack areas. With a full portfolio of engineered refractories, we help blast furnace operators reduce the number of repairs, heat losses, fuel rates, costs and meet today’s environmental standards.

Solution By Application

Click on your application to find more:

Tap Hole Clay

High Performance and Operational Safety

Saint-Gobain Performance Ceramics & Refractories’ high performance tap hole clay provides excellent blast furnace hearth protection, considerably increasing its service life, reducing the risk of stoppages and lowering overall maintenance costs.

Saint-Gobain Performance Ceramics & Refractories offers a comprehensive portfolio of high performance tap hole mixes suitable for every size of blast furnace. A unique combination of the finest raw materials, industry-leading technology, expertise and experience of current furnace conditions ensures that

Saint-Gobain Performance Ceramics & Refractories’ range of custom products offers:

- Increased tap hole lengths

- Stable and long tapping time

- Excellent furnace hearth protection

Unique fast sintering materials are also available for consecutive tapping operations in small furnaces, alongside expansive clays for furnace blow-ins and a crack closing technology for damaged tap hole ‘mushrooms‘.

Saint-Gobain Performance Ceramics & Refractories offers:

- Customized solutions

- Local technical support

- Environmentally friendly product lines

- Strong and stable partnerships with customers

- State-of-the-art technology

Main benefits

Features and Benefits

| Applications | Products | Characteristics | Benefits |

| Small Furnaces | CL | Soft tap hole mix | Minimal splashing during casting |

| Medium and Large Furnaces | SR | Resistance to erosion and corosion by iron and slag | Allows stable operation |

| Consecutive Taps | SR Consecutive | Quick hardening | Enables safe operation when the blast furnace runs with a single taphole |

| Demanding Conditions | SR HP | High adhesion | Maximum protection of hearth wall |

| All Furnaces | EcoTap | Ecological binder | Decresead amount of hazardous compounds released during use |

FAQ

How does Saint-Gobain Performance Ceramics & Refractories’ tap hole clay help to reduce operation costs?

Saint-Gobain Performance Ceramics & Refractories tap hole clay boasts a unique microstructure and enhanced properties, maximizing pig iron production while maintaining a strong and stable mushroom. As such a low volume of clay is required to plug the tap hole after each casting, routine use of Saint-Gobain Performance Ceramics & Refractories tap hole clay will result in much lower operating costs, versus similar materials available in the market.

How does using a high performance tap hole clay help to ensure stable and efficient blast furnace processes?

Clay performance has a direct impact on a furnace’s operational stability, as this dictates the effectiveness of controlled liquid drainage. The tap hole clay formulation must offer an integrated solution based on three key considerations:

- High corrosion resistance

- Good adhesion properties

- Adequate plastic behavior