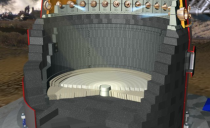

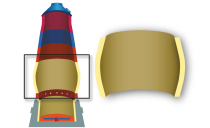

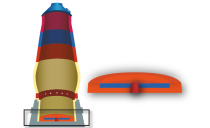

Detailed feedback from users has shown that the “Coranit®” grade wears very gradually over the lifetime of the hearth. 400 mm thickness of Ceramic Cup wall has been shown to last 9 years or more. After the Ceramic Cup has worn, the carbon then wears quite rapidly until an equilibrium is reached whereby the hot face is sufficiently cooled to allow a self-protecting “skull” to form.

Lifetime of the hearth can be increased even more using up to 600 mm Ceramic Cup wall thickness and the 3rd generation Coranit® SlagR.

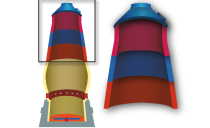

| Blast Furnace Area | Materials Solutions | ||

| Upper stack | Refrax® 20 SBF Nitride bonded Silicon Carbide |

SiC 85P Silicon Carbide Base |

|

| Lower stack | Sicanit Al3 Silicon Carbide Base Sialon Bond |

Refrax® 20 SBF Nitride bonded Silicon Carbide |

|

| Bosh and Belly | Sicanit Al3 Silicon Carbide Base Sialon Bond |

Refrax® 20 SBF Nitride bonded Silicon Carbide |

Coranit® 3S High Alumina Corundum Sialon bond Low thermal conductivity Mortar 336 |

| Tuyere belt | MonoCoral High Alumina Precast Ultra-Low Cement

|

MonoGuard High Alumina Precast no cement |

Sicanit TB Silicon Carbide Base Sialon Bond |

| Hearth | Coranit® AL High Alumina Corundum Sialon bond |

Coranit® SlagR High Alumina Corundum Sialon bond 3rd generation |

|

| Ceramic Pad | MS4F High Alumina |

||

| Quantity of Reference | Materials | Date |

| 15 | MonoCHROMCOR | Since 1984 |

| 27 | MonoCORAL | Since 1985 |

| 17 | CORANIT® | Since 1991 |

| 34 | CORANIT® AL | Since 2002 |

| 4 | CORANIT® SlagR | Since 2018 |

FAQ

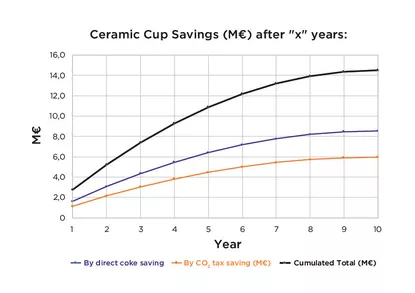

How can Ceramic Cup help to save CO2 emissions and lower coke/energy consumption?

Saint-Gobain’s third generation Ceramic Cup quality Coranit SlagR has improved resistance to iron, slag alkali corrosion and wears very gradually over the lifetime of the hearth.

With its insulating effect compared to a pure carbon hearth the Ceramic Cup reduces the coke consumption and the CO2 emission at the same time.

With the CO2 certificate trading already existing in Europe and for other regions/countries to come (e.g. China*) the money saving effect will become a more and more important factor.

Total CO2 Savings 65KT Total Coke Savings 20KT

Graph: Case study calculated on an existing blast furnace with ceramic cup (hearth diameter 11m)

How can the Ceramic Cup in Coranit SlagR extend the hearth wall lifetime?

The Coranit® Ceramic Cups wear very gradually over the lifetime of the hearth and is the first life of the hearth. After it is worn second hearth life with carbon wall lining continues.

The second generation Ceramic Cup quality Coranit AL with its 34 references over the last 20 years was proven to last >10 years.

Saint-Gobain’s third generation Ceramic Cup quality Coranit® SlagR has improved resistance to iron, slag alkali corrosion and is expected to last an additional two - three years compared to its predecessor Coranit® AL.

Documents

Related Content

Blast Furnaces Refractories

Descubra a gama de soluções refractárias da Saint-Gobain Performance Ceramics & Refractories para aumentar a vida útil dos altos-fornos.

Blast Furnace Repairs

Discover Saint-Gobain Performance Ceramics & Refractories’ shotcrete and castable materials – ideal for interior blast furnace repairs.

High Performance Materials in Blast Furnaces

Saint Gobain High Performance Ceramics and Refractories supplies a wide range of precision materials for industrial applications, including blast furnaces

Related Products

Upper and Lower Stack Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of brick and shotcrete solutions for the upper and lower stack.

Belly and Bosh Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide or corundum-based bricks – ideal belly and bosh solutions.

Ceramic Pad Products

Discover Saint-Gobain Performance Ceramics & Refractories’ range of pad bricks – available in circular or herringbone designs.