Specialty Ceramics

High-performance advanced ceramics for extreme conditions

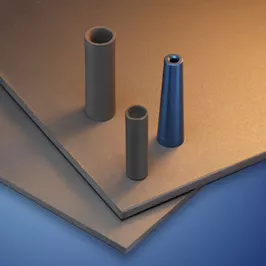

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

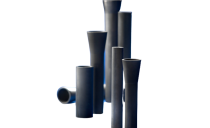

Nozzles

Abrasive Blasting Nozzles and FGD Nozzles

The extreme hardness of sintered silicon carbide and hot pressed boron carbide makes these materials excellent choices for nozzles and wear pads in high wear applications.

Hexoloy® SA SiC and Norbide® B4C nozzles outlast tungsten carbide and demonstrate proven performance in abrasive blasting and atomization applications.

Silit® SKG SiSiC and Hexoloy® SA SiC spiral nozzles are frequently used for flue gas desulfurization (FGD) in power plants.

FAQ

What advantages does boron carbide offer over silicon carbide?

Boron carbide is lighter and harder than silicon carbide.

What advantages do silicon carbide and boron carbide nozzles have over tungsten carbide?

Both silicon carbide and boron carbide are lighter materials than tungsten carbide, while also offering superior hardness. These key factors enable easier nozzle handling and longer service life.

What are the advantages of using silicon carbide nozzles in power plants?

Hexoloy® SiSiC and Silit® SiSiC offer excellent chemical corrosion resistance and abrasion resistance. This makes these materials ideally suited to the harsh environment typically found in flue gas desulfurization units in power plants.