Ironmaking

General Areas Served

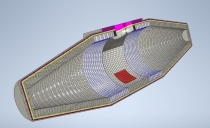

Blast furnace

Challenging conditions affect every area of a conventional blast furnace. For the hearth pad and hearth wall, tuyere belt, bosh and belly, lower and upper stack the lining of these areas has to deal with elements such as molten iron, corrosive vapors and abrasion from the solid burden. Raw materials entering through the throat may be a source of wear and tear, while coarse particles and carbon monoxide-rich gases produced as by-products can cause problems from the bottom up.

At Saint-Gobain Performance Ceramics & Refractories, we develop advanced, sustainable solutions for every stage of ironmaking. Our Coranit® Al and SlagR ceramic cup technology reduces CO₂ emissions and extends furnace life. We offer castable and shotcrete options for various furnace repairs, including the hearth and stack areas. With a full portfolio of engineered refractories, we help blast furnace operators reduce the number of repairs, heat losses, fuel rates, costs and meet today’s environmental standards.

Solution By Application

Click on your application to find more:

- Blast Furnaces Refractories

- Blast Furnace Repairs

- Tap Hole Clay

- Torpedo Car (Torpedo Ladle)

Blast Furnace Repair Solutions

Solutions to extend Blast Furnace life-time

With blast furnace service lives typically extending to 20 years or more, it is essential that effective intermediate refractory repairs are performed to address advancing wear in areas such as the stack, tuyere, tap holes, hearth walls and pad.

Saint-Gobain Performance Ceramics & Refractories offers castable solution, ideal for hearth wall, tap hole, tuyere and bosh repairs:

Sialfrax™ 18 Cast (colloidal silica bonded) for reprofiling and tap hole repairs in the hearth.

Products for Blast Furnace Repair

| Area | Main wear mechanism | Suitable Product |

| Hearth | Molten Iron/Slag Erosion | Sialfrax™ 18 Shot+ Sialfrax™ 18 Cast+ |

| Lower Stack | Abrasion / Strong Alkali Attack | Sialfrax™ 18 Shot+ |

| Middle and Upper Stack | Abrasion at < 1,000°C | Sialfrax™ 18 Shot+ |

FAQ

What are the benefits of utilizing colloidal silica materials in the lower stack, belly and bosh?

Sialfrax™ 18 Cast demonstrates high mechanical strength at high temperature, while its SiC content ensures high alkali and abrasion resistance.

What is the benefit of performing regular hearth repairs?

While regular hearth repairs will not eliminate the eventual need for a full blast furnace reline, they offer significant operational benefits. These include:

- Minimizing Unplanned Downtime: Timely repairs help prevent unexpected failures that could lead to costly production interruptions.

- Extending Campaign Life: By addressing localized wear and damage, repairs can prolong the interval between full relines.

- Improving Safety and Reliability: Maintaining the integrity of the hearth reduces the risk of critical failures and enhances overall furnace stability.

- Cost Efficiency: Smaller, scheduled interventions are generally more economical than emergency shutdowns or premature relining.

In short, regular hearth maintenance is a strategic approach to maximizing furnace uptime and optimizing lifecycle costs.