Specialty Ceramics

High-performance advanced ceramics for extreme conditions

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

Semiconductor Wafer Processing

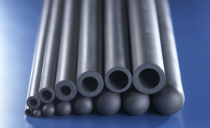

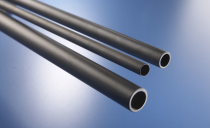

Silicon Carbide Components

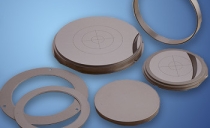

A range of Hexoloy® SA and SG components can be used in semiconductor wafer processing equipment, including vacuum chucks, chemical mechanical polishing (CMP) blocks and wafer carrier trays.

These applications take advantage of Hexoloy silicon carbide's thermal expansion match to silicon, high elastic modulus, chemical inertness, and high thermal conductivity. Hexoloy silicon carbide is well suited as a structural material for low mass wafer carrier components, and rigid dimensionally stable platforms with exceptional flatness for wafer grinding, lapping, and polishing.

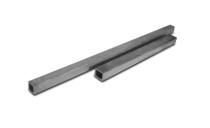

Silit® SK SiSiC and Advancer® NB SiC materials are used in the air-bearing stages of semiconductor metrology positioning equipment.

Features and Benefits

- Structural strength and thermal expansion close to that of silicon wafer

- Chemical corrosion resistance

- Thermal stability

- A range of electrical resistivity

Sintered Silicon Carbide Materials For Semiconductor Processing

FAQ

Does Saint-Gobain Performance Ceramics & Refractories offer products for semiconductor wafer inspection metrology equipment?

Silit® SiSiC and Advancer® NB SiC products are used in the construction of air-bearing stages for positioning equipment.

How is sintered silicon carbide typically used in semiconductor wafer processing applications?

Hexoloy® sintered silicon carbide can be used in a wide range of components, including:

- Vacuum chucks

- Reactor tubes for thermal oxidation

- Wafer grinding and polishing plates

- Thermocouple protection tubes

- Wafer carrier trays

- Clamps and lift pins

- Sputtering targets

Is Hexoloy® SiC pure enough to be used in semiconductor wafer processing?

Hexoloy® sintered silicon carbide is essentially a single-phase material with at least 98% SiC.

At this purity, Hexoloy® can be successfully used at low to moderate temperatures in wafer contact applications, and up to 1,300°C in non-contact applications.