Features and Benefits

- High oxidation resistance - up to 1,650°C in air

- Excellent corrosion resistance against a wide range of chemicals

- High mechanical strength, erosion and abrasion resistance

- Superior resistance to thermal cycling

- Process tubes

- Sparger tubes

- Sensor tubes

Typical Properties of Hexoloy® SA

| Property | Units | Typical Value |

| Composition* | - | SiC |

| Grain Size | µm | 4.10 |

| Density | g/cm3 | 3.15 |

| Hardness (Knoop)** | kg/mm2 | 2,800 |

| Flexural Strength 4 pt @ RT*** | MPa x103 lb/in2 | 380 55 |

| Flexural Strength 3 pt @ RT*** | MPa x103 lb/in2 | 550 80 |

| Compressive Strength @ RT | MPa x103 lb/in2 | 3900 560 |

| Modulus of Elasticity @ RT | GPa x106 lb/in2 | 430 62 |

| Weibull Modulus (2 parameter) | 10 | |

| Poisson Ratio | 0.14 | |

Fracture Toughness @ RT Double Torsion & SENB | MPa x m1/2 x103 lb/in2 x in1/2 | 4.60 4.20 |

Coefficient of Thermal Expansion RT to 700°C | x10-6 mm/mmK x10-6 in/in ˚F | 4.02 2.20 |

| Maximum Service Temp. Air | °C °F | 1,900 3,450 |

| Mean Specific Heat @ RT | J/gmK | 0.67 |

Thermal Conductivity @ RT @ 200°C @ 400°C

| W/mK Btu/ft h °F W/mK Btu/ft h °F W/mK Btu/ft h °F | 125.6 72.6 102.6 59.3 77.5 44.8 |

| Permeability @ RT to 1000°C | Impervious to gases over 31 MPa | |

Electrical Resistivity @ RT**** @ 1000°C | ohm-cm ohm-cm | 102 - 108 0.01 - 0.2 |

| Emissivity | 0.9 |

Tube diameters can range from 25 mm to 381 mm with lengths up to 1.4 m. Longer tubes (up to 4.9 m) are available as assemblies using a proprietary bonding process.

Process tubes may also be manufactured via extrusion (Hexoloy® SE) for applications requiring long tubes (up to 5 m) without joints.

Industries Served

Aerospace

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics – designed for essential components in the aerospace industry.

Automotive and Electric Vehicles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of solutions for the automotive market.

Chemical

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics solutions for the chemical market.

Electronics & Semiconductors

From pacemakers to pain suppression devices, our ceramics enable fabrication of critical electronic components for the medical, sensor, and consumer...

Related Products

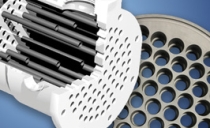

Hexoloy SE Sintered Silicon Carbide Tubes and SA Tube Sheets

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide products for shell and tube heat exchangers.