- Improved kiln capacity and flexibility

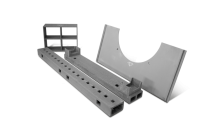

- Stable construction

- Increased automation compatibility for loading and unloading

- High thermal shock and oxidation resistance

- Reduced firing cycles

- Enhanced safety

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modolus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| N-Durance® | 70 | 1450 | 2.75 | ≤ 1 | 170 – 180 | 170 – 190 | 4.4 |

Suitable for firing a diverse range of sanitaryware, dinnerware, electronics and semiconductors, automotive DPF/GPF, and technical ceramics.

FAQ

Are standard sizes available?

No. All products are designed to customer specifications to ensure maximum service life and loading space.

Related Content

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

Diesel Particle Filters and Gas Particle Filters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of LO-MASS® kiln furniture - excellent strength, shape and assembly stability for large...

Technical Ceramics Application

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of engineered ceramics and refractories – highly suited to producing high...

Sanitaryware and Dinnerware

Discover Saint-Gobain Performance Ceramics & Refractories’ sanitary and dinnerware solutions – advanced kiln furniture systems able to reduce energy...

Related Products

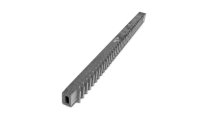

Crystar® Lug Posts

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic components for kiln car and kiln rack constructions - enabling...