The outstanding combination between the superior properties of R-SiC and our compact crossflow geometries elevates the capacities of crossflow membrane filtration processes to new standards.

Exploring the Benefits of Crystar® Crossflow Filtration

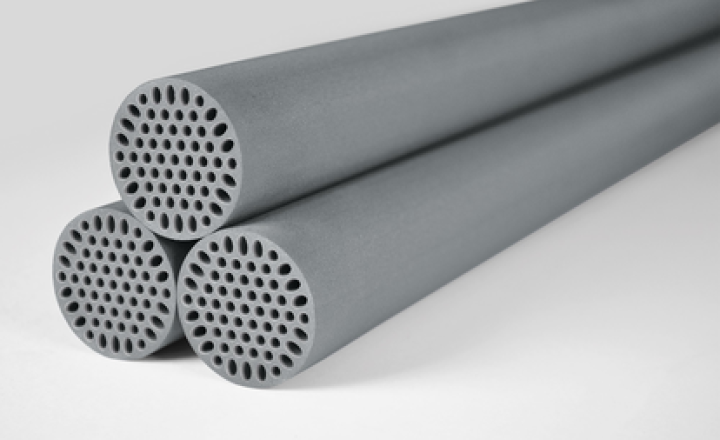

Crystar® FT crossflow membranes were developed for the most demanding applications. Thanks to their well-engineered and well-controlled R-SiC microstructure, filtration processes of high value products can be achieved consistently. The carrier geometries were designed with the support of numerical modelling for an optimal combination of filtration fluxes, longitudinal pressure drop and mechanical resistance. To summarise, Crystar® FT crossflow membranes provide:

- Reliable separation processes thanks to the well-engineered and thoroughly controlled multi-layer silicon carbide membrane,

- Low energy consumption resulting from high permeate fluxes at low transmembrane pressures and low recirculation speed,

- Fast and effective CIP cycles enabled by the unmatched thermal shock resistance, thermal stability and corrosion resistance for harsh cleaning operations,

- High compactness thanks to the high filtration area developed in big size tubular carriers combined with high permeate fluxes,

- Efficient backwash operations thanks to high carrier permeability and low adsorption of negatively charged compounds (bacteria, proteins, oils,…).

Products

|

Membrane Pore Sizes |

|||

| 250 nm | 600 nm | 1000 nm | 3000 nm |

| Geometries | |||

| Outer Diameter (mm) | Channels Diameter (mm) | Filtration Area (m2/m) | Length (mm) |

| 10 | 6 | 0.018 | up to 400 mm |

| 25 | 17 | 0.053 | up to 1178 mm |

| 25 | 3 | 0.3 | up to 1178 mm |

| 25 | 2 | 0.43 | up to 1178 mm |

| 41 | 3 | 0.66 | up to 1200 mm |

*Mercury intrusion is a reliable and known method to measure the physical pore size of porous materials.

Documents

Related Products

Crystar Deadend

Crystar® FT’s proprietary dead-end technology uses multi-layered membranes of recrystallized silicon carbide (R-SiC) carried by a unique honeycomb monolith...

Related Content

Wine Clarification

Crossflow microfiltration is a key step to ensure the sensorial properties and stability of wines, which are of utmost importance to the product value.

Beer Clarification

Provide a high productivity and cost-effective solution to reduce haze in the finished beer in order to ensure its visual quality and contribute to its...

Coconut Water Clarification

Coconut water clarification is a crucial part of the production process, due to the high turbidity and presence of microorganisms such as C. botulinum...

Crystar Ceramic Membrane Filters for water and wastewater treatment

Crystar® ceramic membrane filters are high-performance filters developed to tackle the most difficult liquid microfiltration applications