Key Benefits of SiC Filtration Membranes

- High filtration flow rates

- Low energy operation

- Compact installations

- High water recovery

Material Description and Applications

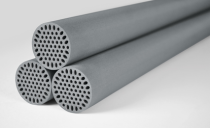

Crystar® FT dead-end membranes feature alternately plugged channels that define distinct flow paths for feed and permeate streams. Liquid enters through open inlet channels and is forced across the membrane-coated porous honeycomb walls, exiting through outlet channels. With a wall thickness of 0.9 mm and 40% porosity, these membranes offer minimal resistance to fluid flow, ensuring efficient filtration and backwashing. Despite their compact size, each silicon carbide membrane provides a substantial 16m² filtration area due to the internal honeycomb geometry.

Crystar® HiFlo and HiFlo A+ are SiC membranes with a 4 µm pore size. They provide an excellent trade-off between productivity and permeate quality. They can replace traditional technologies such as sand, bag and cartridge filters with significant compactness, filtrate quality, maintenance and OPEX benefits.

Crystar® HiPur and HiPur A+ are SiC membranes with a 0.25 µm pore size. The tight and well-controlled pore size distribution offers the best solution to reach uncompromising filtrate qualities, mostly equivalent to those provided by 50 – 100 nm ultrafiltration membranes.

Crystar® FT is successfully used across the full spectrum of water treatment. If you would like to learn more about our proprietary dead-end filtration membranes, contact us using the link below.

FAQ

What are the advantages of dead-end filtration?

Dead-end filtration offers several advantages, including simplicity of design, ease of operation, and cost-effectiveness due to the absence of a recirculation loop. It provides high filtration efficiency and reduced energy consumption as the entire feed flow passes through the membrane, maximizing available surface area. This method also ensures effective retention of particulates and microorganisms, making it suitable for applications requiring stringent filtration standards.

What is the difference between crossflow and dead-end filtration?

Crossflow and dead-end filtration differ primarily in flow dynamics and operational efficiency. In crossflow, the feed stream flows tangentially across the membrane surface, allowing continuous removal of retained particles and reducing fouling. This makes it ideal for high-solids applications and long-term operation. Dead-end filtration, on the other hand, directs the feed perpendicular to the membrane, with all feed passing through the membrane, which is simpler and more cost-effective for low-solids applications but more prone to fouling and frequent cleaning requirements.

What can SiC membranes remove?

Crystar® FT ceramic membrane filters effectively remove hazardous microorganisms and contaminants from various liquid feeds, suitable for applications such as drinking water production, wastewater treatment, recreational water filtration, and industrial wastewater recycling. They are adept at filtering bacteria, viruses, protozoa, particulates, colloids, suspended solids, impurities, and oil droplets. Key advantages include high porosity, purity, consistent retention capabilities, high filtration fluxes, and robust silicon carbide construction, which ensures resistance to harsh chemicals and high temperatures.

Realize 45% water and energy savings with Crystar® FT

Documents

Related Content

Wastewater Treatment

Crystar® FT is poised to interrupt this cycle of consumption and pollution by providing a cost-effective solution for the filtration of challenging and...

Drinking Water Production

Crystar® liquid filtration technology offers excellent levels of efficiency in terms of microorganism retention and particulate removal, combined with high...

Swimming Pool

Ceramic membranes for recreational water filtration can drastically reduce the environmental footprint of aquatic centers and improve the cleaning and...

Crystar Ceramic Membrane Filters for water and wastewater treatment

Crystar® ceramic membrane filters are high-performance filters developed to tackle the most difficult liquid microfiltration applications

Related Products

Crystar Crossflow

Crystar® FT’s proprietary crossflow technology uses multi-layered membranes of high purity recrystallized silicon carbide (R-SiC) supported by the most...