Crystar® Filtration Technology

Material Properties

Crystar® filtration technology (FT) is engineered using silicon carbide (SiC), an outstanding ceramic material with a myriad of advanced mechanical, thermal, and chemical properties. Recrystallized SiC (R-SiC) material is a special grade of SiC obtained through a sublimation/condensation process at temperatures above 2,000°C. This process eliminates nano-particles to create a microstructure with excellent permeability to various fluids.

Key benefits of Crystar® FT

Thanks to the well-controlled and engineered microstructure of high-purity R-SiC from the membrane to the carrier, Crystar® FT membranes and filters feature:

- Enhanced permeate fluxes for gases and numerous liquid types, from surface water to wine, enabling higher throughput filtration at lower operating costs with more compact and lighter installations.

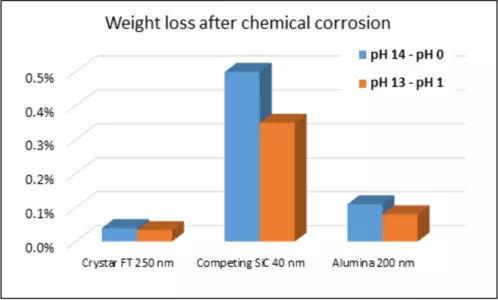

- Superior thermal and chemical resistance to corrosive agents from pH 0 – pH 14, allowing the use of harsh cleaning agents and the filtration of aggressive fluids.

Chemical corrosion resistance benchmark – Weight loss after 200 hours soaking in sodium hydroxide at 80°C followed by 200 hours soaking in nitric acid at 80°C

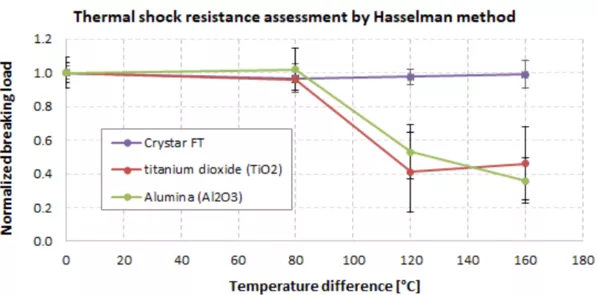

- High thermal shock (fast temperature variations) resistance, due to the combination of high thermal conductivity, low thermal expansion, and high mechanical resistance. This enables shorter cleaning cycles at high temperature without risking structural damage to the filtration media.

Thermal shock measurements following the Hasselman method – Quenching of 150 mm tubular membranes in cold water followed by evaluation of residual mechanical strength

- Low adsorption of organic matter and other negatively charged compounds, thanks to the inherently negative surface charge of R-SiC, enabling fast and efficient cleaning procedures in highly fouling liquids such as those with natural organic matter (NOM) content.

- Excellent retention efficiency, with demonstrable success in strongly reducing high levels of suspended solids, bacteria, oil, and other particulates in challenging streams.

Lastly, R-SiC is an inert, non-toxic material. Our Crystar® membranes have certifications for food contact in Europe (EU 1935-2004), and are deemed acceptable for food and beverage processing according to the FDA.

Crystar® FT products were designed to improve sustainability and efficiency in a variety of filtration processes. They have provided excellent clarification in the food and beverage sector, high efficiency for oil / water separation, safety for recreational water facilities, and much more.

Achieve M.O.R.E. with Crystar® FT

Our Crystar® technology is based on a proprietary arrangement of recrystallized silicon carbide (SiC) layers, featuring a naturally negative surface charge like most microorganisms and natural organic matter. Combined with a well-controlled and engineered pore size range of 0.25 – 4.0μm, this enables an excellent trade-off between permeate flux and retention of microorganisms.

This Micro Organism Retention Efficiency (M.O.R.E.) has been demonstrated without the use of coagulants by measurements performed by renowned laboratories in Europe and the USA. (Measurements performed at Fresenius Institute (Germany), Dresden University (Germany), Firmus (France), University of North Carolina (USA).

Crystar® FT Membranes Filtration Efficiency

| Crystar® HiPur (0.25 µm R-SiC membrane) | ||

| MS2-Phagen virus (30 nm) | LRV = 1.7 | 98% efficiency |

| Legionnella adelaidensis (0.5 x 2.0 µm) | LRV > 5.0 | >99.999% efficiency |

| Pseudomonas aeruginosa (0.5 x 2.0 µm) | LRV = 5.1 | 99.9992% efficiency |

| Crystar® FT600 (0.6 µm R-SiC membrane) | ||

| Escherichia Coli (size 0.5 µm x 1.5 µm) | LRV = 4.2 | 99.992% efficiency |

| Brevundimonas diminuta (0.2 µm x 0.5 µm) | LRV > 3.7 | 99.97% efficiency |

| Crystar® HiFlo (4 µm R-SiC membrane) | ||

| Cryptosporidium Parvum (4.5 µm) | LRV = 4.4 | 99.996% efficiency |

| Giardia lamblia (10 µm) | LRV > 4.5 | 99.997% efficiency |

| Legionnella adelaidensis (0.5 x 2.0 µm) | LRV > 3.6 | 99.96% efficiency |

| Pseudomonas aeruginosa (0.5 x 2.0 µm) | LRV = 1.5 | > 97% efficiency |

Crystar® filtration technology supports the effective elimination of hazardous microorganisms in various liquid feeds and different applications. For instance, it provides effective cryptosporidium filtration in recreational water, E.coli retention in drinking water, and legionella removal from sanitary hot water.

Crystar® membranes and filters provide M.O.R.E. in every sense of the word. They are cost-effective alternatives or performance enhancement complements to disinfection technologies for improved safety and efficiency in terms of microorganism removal.

Related Products

Crystar Crossflow

Crystar® FT’s proprietary crossflow technology uses multi-layered membranes of high purity recrystallized silicon carbide (R-SiC) supported by the most...

Crystar Deadend

Crystar® FT’s proprietary dead-end technology uses multi-layered membranes of recrystallized silicon carbide (R-SiC) carried by a unique honeycomb monolith...