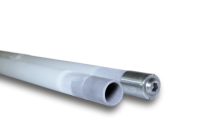

Silicon carbide radiant tubes can withstand application temperatures up to 1,380°C and can input up to twice as much energy into furnaces as alloy radiant tubes.

Features and Benefits

Benefits

- Made of robust silicon carbide

- Operating temperatures up to 1,380°C

- Long service life

- Advanced silicon carbide microstructures provide high thermal conductivity and shock resistance

- Industry-leading diameter and length

- Suitable for most furnace applications

- Thin-wall designs increase thermal performance and enable design flexibility

Benefits

- Long service life

- High thermal strength

- Able to outperform metal tubes without any bending

- Customized production options

- Reduced furnace running costs

- Reduced maintenance frequency

- Use especially for horizontal heat treatment of thick steel sheets

FAQ

What is the maximum application temperature for Silit® SKD ceramic radiant tubes?

The maximum application temperature is 1,380°C.

What are the maximum dimensions for Silit® SKD ceramic radiant tubes?

The maximum dimensions are 300 mm in diameter and 3,500 mm in length. Radiant tubes can be customized to accommodate customer-specific mounting requirements.

What is the difference between ceramic and metal radiant tubes?

Ceramic radiant tubes made from Silit® provide twice the heat transfer rate (50 kW/m2 – 1,050°C) of a standard metallic radiant tube. Ceramic radiant tubes do not require bending, meaning their service life is longer versus a metallic tube.

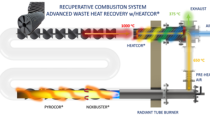

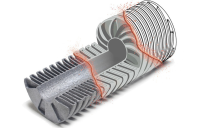

What is different between HeatCor™ and a standard recuperator?

The HeatCor™ technology’s use of hollow channels and the resultant larger inner surface area results in an increase of up to 80% efficiency versus a standard ceramic recuperator.

How does PyroCor™ work?

PyroCor™ utilizes a specialized design and variable twists to optimize temperature uniformity in the radiant tube.

What are the material properties of Silit® and Amasic-3D™?

These infiltrated SiSiC high performance, non-porous ceramic materials can accommodate application temperatures of 1,380°C. They also offer excellent thermal strength properties.

What is the minimum wall thickness possible with Silit® and Amasic-3D™?

The thinnest possible wall thickness is approximately 4 mm with Silit® and 2 mm with Amasic-3D™.

What is the difference between Silit® SKD, Silit® SKD-H and Hexoloy®?

The key difference of Silit® SKD, Silit® SKD-H and Hexoloy® is the range of application temperatures which can be accommodated. Hexoloy® is 100% SiC while Silit® has a percentage of silicon in the matrix. This allows Hexoloy® to operate at temperatures exceeding 1,800°C.

Can ceramic radiant tubes be cantilever mounted?

Their high thermal strength allows all ceramic radiant tubes from Saint-Gobain Performance Ceramics & Refractories’ to be cantilever mounted.

Documents

Related Content

Total Burner Solution for Energy Efficiency and Carbon Reduction

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of total burner solutions for industrial heating applications.

Radiant Refractory Tubes: Properties & Applications

Saint-Gobain radiant refractory tubes can output as much as twice the energy of standard alloy radiant elements into furnace environments.

Direct & Indirect Heating Burner Solutions from Saint-Gobain

As producers look for ways to push their industrial heating processes to higher efficiencies and outputs, they are faced with new challenges.

A New Spin on Zinc Melting Furnaces

Saint-Gobain close the technology gap with the introduction of their enhanced SpyroCor® flame diffuser insert for immersion tube furnaces.

Related Products

PyroCor and Silit Flame Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of flame tubes and diffusers – ideal for guiding the flow of combustion.

HeatCor and Silit Recuperators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of recuperators for integration into burner systems.

Amasic-3D Burner Nozzles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of burner nozzles – ideal for guiding the flow of combustion.

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.

DuraFORM® Rollers

Découvrez les rouleaux en carbure de silicium DuraFORM® de Saint-Gobain Performance Ceramics & Refractories, idéaux pour les fours à sole roulante à haute...