A robust bonding system and carefully selected raw materials ensure high adhesion, superior strength and resistance to the harsh conditions commonly found inside the boiler.

Features and Benefits

- Monolithic rammable

- Robust silicon carbide base

- Heat setting

- Low shrinkage

- Time saving and easy to use

- Reliable

- Flexible

- Compatible with tile systems for a fully integrated solution

- Packaged in a 25 kg bag

- A shelf life of 6 months under normal conditions

ProRam 80

| Property | Value | Method | ||||||||

| Typical Chemical Analysis |

|

DIN EN ISO 21068 DIN 13925 DIN 51001 |

||||||||

|

Loss on Ingnition at 700ºC (direct) |

<0.3% |

BS 812 -2:1995 | ||||||||

| Particle Sizing | <3 mm | DIN EN 933-1 DIN EN 933-2 |

||||||||

| Cold Crushing Test after 3hrs MST | 50 MPa | BS EN 993-10:1998 | ||||||||

| Maximum Use Temperature | 1,450ºC | |||||||||

| Permanent Linear Change at 110ºC after 3hrs MST |

<1% <1% |

BS EN 993-10:1998 | ||||||||

| Rammed Density | 2550 Kg.m-3 |

|||||||||

| Bulk Density after 3hrs MST | 2.40 g.cm-3 | BS EN 993-1:1995 | ||||||||

| Abrasion resistance at MST | 20 cm-3 | BS 1902 : 4.6 : 1985 | ||||||||

| Thermal Conductivity at 800ºC | 3.0 W.m-1k-1 | BS 1902 - 5.5: 1991 | ||||||||

| Moisture, as received | 6% | BS 812 - 7.6: 1975 |

- Inlet roof

- Burner outlet

- Super heater

- Header and collector

- Repairs and patching

Documents

Related Content

Waste to Energy Solutions with Silicon Carbide

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high performance refractory solutions for thermal waste treatment in waste to energy...

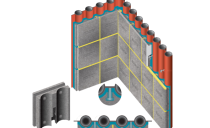

Back Cast SiC Tube Wall Tile Systems

Discover Saint-Gobain Performance Ceramics & Refractories’ T-Clip® range of tile systems. Simple self-leveling back castable products ensure optimum...

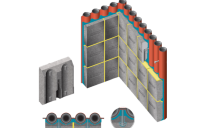

Mortar SiC Tube Wall Systems

Discover Saint-Gobain Performance Ceramics & Refractories’ traditional mortared tile system – simple, rapid replacement, even of individual wall tiles.

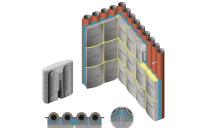

Custom Designed SiC Tube Wall: Tile or Brick

Saint-Gobain Performance Ceramics & Refractories offers a robust combination of experience and expertise in the manufacture of custom silicon carbide...

Related Products

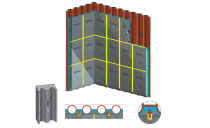

T-Clip® PRO System - Furnace Tube Protection

Discover Saint-Gobain Performance Ceramics & Refractories’ T-Clip® PRO - an optimized backfilled tile system offering maximum protection for vertical...

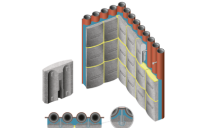

T-Clip® PROform System

Saint-Gobain Performance Ceramics & Refractories' T-Clip® PROform™ system a unique, patented tube protection system able to lower mean tile temperatures...

45° System

Discover Saint-Gobain Performance Ceramics & Refractories’ 45° mortared system, suitable for all installation systems.

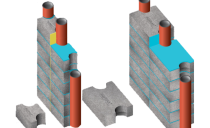

Belly Brick System

Discover Saint-Gobain Performance Ceramics & Refractories’ belly brick system - straightforward protection for single tube walls with no metallic fixing...

Refrax® ProMor and PLUSflow - Mortar

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProMor and PLUSflow mortars - the backbone of its tile systems for waste to energy...

Refrax® PRO, PLUS, and TOP tiles

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® PRO, PLUS and TOP waste to energy tiles.

Refrax® ProCast - Castable

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProCast – a silicon carbide castable for waste to energy applications.

Refrax® ProGUN - Gunning

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProGUN range of gunning mixes for waste to energy applications.

Refrax® ProPlast - Plastic

Discover Saint-Gobain Performance Ceramics & Refractories’ Refrax® ProPlast plastic mass for waste to energy applications.

Refrax® GT Max

The Refrax® family of nitride and oxynitride bonded silicon carbide materials utilize carefully selected raw materials with specific attention paid to...