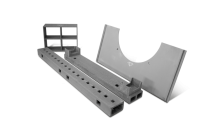

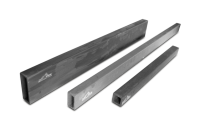

A large selection of cross-sections, wall thickness, and lengths are available, with cross-sections as small as 12.5 mm and lengths up to 3,500 mm. Beams are formed using slip-casting or extrusion processes, suitable for use ‘as-is’ or finished according to customer’s required tolerances.

Features and Benefits

Specifications

- Advanced nitride-bonded silicon carbide construction

- Excellent oxidation resistance

- High strength

- Provide structural support in kiln and furnace applications below 1,450 °C

Typical Chemical Analysis & Physical Properties

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modulus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| N-Durance® | 70 | 1,450 | 2.75 | ≤ 1 | 170 – 180 | 170 – 190 | 4.4 |

Specifications

- Advanced siliconized silicon carbide construction

- Excellent oxidation resistance

- High strength

- Able to provide structural support in kiln and furnace applications below 1,380 °C

Typical Chemical Analysis & Physical Properties

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modulus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| Silit® SK | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

| Silit® SKD | 85 | 1,350 | 3 | 0 | 260 | 260 | 4.5 |

Specifications

- Advanced sintered silicon carbide construction

- Ultimate high-temperature resistance

- High strength

- Able to provide structural support in kiln and furnace applications up to 1,900°C

Typical Chemical Analysis & Physical Properties

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modulus of Rupture | Thermal Expansion αRT 1,200°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,450°C) | (10-6/K) | |

| Hexoloy® SE | > 98 | 1,900 | 3.05 | 5.10 | 280 | 270 | 4.02 |

Specifications

- Advanced recrystallized silicon carbide construction

- High-temperature resistance

- High strength

- Able to provide structural support in kiln and furnace applications up to 1,600 °C

Typical Chemical Analysis & Physical Properties

| SiC-content | Max. Service Temperature | Bulk Density | Apparent Porosity Vol. | Modulus of Rupture | Thermal Expansion αRT 1,100°C | ||

| (%) | (°C) | (kg/dm3) | (%) | (RT2) | (1,400°C) | (10-6/K) | |

| Crystar® 2000 | > 99 | 1,600 | 2.7 | 15 | 80 | 90 | 4.8 |

| Crystar® 3000 | > 97 | 1,600 | 2.7 | 15 | 80 | 90 | 4.8 |

Related Content

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

Diesel Particle Filters and Gas Particle Filters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of LO-MASS® kiln furniture - excellent strength, shape and assembly stability for large...

Hot Stamping

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-performance ceramic rollers – ideal for use in all roller hearth kiln zones and...

Glass Technology

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractories – highly suited to the production of high-quality, high...

Technical Ceramics Application

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of engineered ceramics and refractories – highly suited to producing high...

Abrasives and Grinding Media

Discover Saint-Gobain Performance Ceramics & Refractories’ range of kiln furniture systems – ideal for the production of grinding wheels and grinding...

Lithium-Ion Battery Cathode Powders

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-strength silicon carbide rollers – suitable for roller hearth kilns used to...

Sanitaryware and Dinnerware

Discover Saint-Gobain Performance Ceramics & Refractories’ sanitary and dinnerware solutions – advanced kiln furniture systems able to reduce energy...

Related Product

Crystar® and Hexoloy® High-Load Beams

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-load beams - safe support in structural assemblies under extreme loads and at high...

LO-MASS® Kiln Furniture

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of solutions and materials for kilns and furnaces, including kiln furniture...