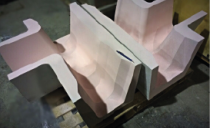

Saint-Gobain Performance Ceramics & Refractories’ dry vibration cement (DVC) forms a monolithic backup lining that eliminates the mortar joints of a traditional brick lining.

The LK-1175 material has been specifically designed for maximum compatibility with Cryston® Cu Max material bricks when utilized in the typical operating conditions of copper shaft furnaces.

Features and Benefits

- Joint-free monolithic safety lining does not allow metal leaks

- High chemical and oxidation resistance

- Matched thermal expansion with Cryston® Cu Max hot face bricks

- Safety lining can be reused by only replacing the hot face brick

- Increased furnace safety due to monolithic backup layer

- Highest refractory performance when used with Cryston® Cu Max

- Rapid, easy installation due to lack of mortar joints

FAQ

Can the safety lining be reused?

Yes. The safety lining can be reused several times.

Can using Saint-Gobain Performance Ceramics & Refractories’ backup lining reduce relining time?

Yes. Time savings of between 5 and 7 days are common on full reline projects due to the backup lining’s faster installation and dry out. Since the backup lining can be reused, time savings on partial reline projects are even greater.

Does the DryVibe powder harden once the furnace is started?

Yes. The material sinters during the heat up phase and becomes monolithic.

Is the safety lining resistant to molten copper leaks?

Yes. The safety lining formulations have been specifically designed to resist copper leaks and copper oxides.

Documents

Related Content

Primary and Secondary Copper Furnaces

Refractory materials from Saint-Gobain Performance Ceramics & Refractories offer excellent performance and extended service life in the most critical...

Holding Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Launders

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractory solutions for molten metal transfer.

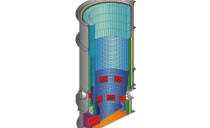

Shaft Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Related Products

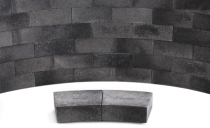

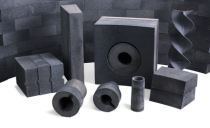

Hot Face Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of silicon carbide hot face bricks for copper furnaces.

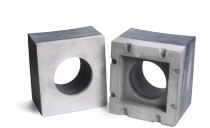

Burner Blocks and Burner Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of burner blocks and burner tubes for copper furnaces.

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

Impact Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of impact bricks for the charging section of copper furnaces.

Firefrax CRM-30 and Carbofrax Series - Mortars

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of specialty mortars for copper furnaces.

Launder Hot Face

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of launders, troughs and tundish refractory components.