This increases the chemical resistance to copper oxide and is not wetted by molten copper.

These properties, coupled with its high temperature mechanical strength, and improved impact and abrasion resistance make Cryston® Cu Max an excellent choice for hot face brickwork.

Saint-Gobain Performance Ceramics & Refractories’ refractory design concept and use of specialized cement ensures minimal slag and refractory inclusion, yielding a potentially cleaner metal.

Features and Benefits

- Patented composition designed for oxidation resistance

- Self-protecting silicon-oxynitride bond phase

- Thermal shock resistance

- High density and deep, uniform nitridation

- High quality silicon carbide grain

- Years of reliable service life

- Assurance of predictable performance in critical equipment

- Low total cost of ownership

- Reduced maintenance costs

FAQ

Does the use of Cryston® Cu Max bricks improve furnace lifetime?

Yes. The average customer gains between 30% and 50% more refractory service life, with some installations, even doubling this.

What is the recommended thickness for the hot face brick?

Standard 115 mm (4.5”) and 150 mm (6”) inch hot face bricks are available. Conversion to thicker linings can be facilitated through the use of DryVibe safety lining.

What mortar is typically recommended for use with hot face bricks?

Different mortars are more suitable for each area of the furnace. Saint-Gobain Performance Ceramics & Refractories’ experienced engineering teams are on hand to provide advice and support around this particular application.

Documents

Related Content

Primary and Secondary Copper Furnaces

Refractory materials from Saint-Gobain Performance Ceramics & Refractories offer excellent performance and extended service life in the most critical...

Holding Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Launders

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractory solutions for molten metal transfer.

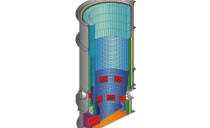

Shaft Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

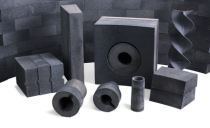

Related Products

C104

Discover the C104 fused cast refractory – an ideal solution for the most demanding furnace applications.

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

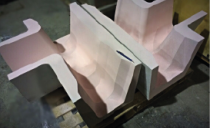

Impact Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of impact bricks for the charging section of copper furnaces.

Back-up Safety Lining

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of backup safety linings for copper furnaces.

Firefrax CRM-30 and Carbofrax Series - Mortars

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of specialty mortars for copper furnaces.

Launder Hot Face

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of launders, troughs and tundish refractory components.