Features and Benefits

- Interlocking crystalline structure formed by electrical melting

- Uniform microstructure produced by slow, controlled cooling of cast ingots

- Extreme high temperature stability

- Exceptional resistance to thermochemical reactions versus conventional bonded refractories

- Extended refractory life in key furnace areas

- Balanced refractory wear avoids premature replacement

- Longer production campaigns and increased profits

- Reduced maintenance costs from fewer shutdowns

FAQ

Can C104 be used in lead (Pb) furnaces?

Yes. C104 can be successfully utilized in lead furnaces. Saint-Gobain Performance Ceramics & Refractories’ experienced engineering teams are on hand to provide advice and support around this particular application.

What are the benefits of utilizing the C104 refractory?

C104 fused cast refractory excels in the most severe wear areas of the furnace. Its exceptional properties enable a balanced wear profile between refractory sections. C104 allows the full thickness of the lining to be utilized and leading to significant savings in operational and maintenance costs.

Documents

Related Content

Primary and Secondary Copper Furnaces

Refractory materials from Saint-Gobain Performance Ceramics & Refractories offer excellent performance and extended service life in the most critical...

Flash Melter

Discover Saint-Gobain Performance Ceramics & Refractories’ complete range of refractory solutions for flash furnaces in primary copper production.

Tap Hole System

Discover the complete range of refractory solutions for copper furnace tap hole blocks.

Related Products

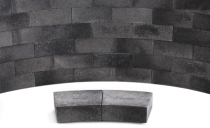

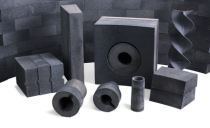

Hot Face Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of silicon carbide hot face bricks for copper furnaces.

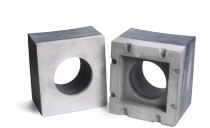

Burner Blocks and Burner Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of burner blocks and burner tubes for copper furnaces.

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

Impact Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of impact bricks for the charging section of copper furnaces.

Back-up Safety Lining

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of backup safety linings for copper furnaces.

Firefrax CRM-30 and Carbofrax Series - Mortars

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of specialty mortars for copper furnaces.

Launder Hot Face

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of launders, troughs and tundish refractory components.