Features and Benefits

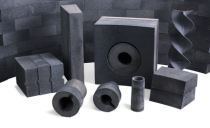

- High density bonded SiC material

- Excellent strength and impact resistance at operating temperatures

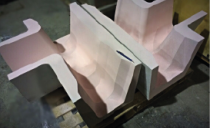

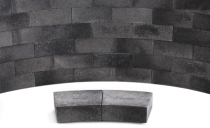

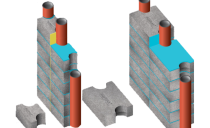

- Arch brick design assures structural stability in the impact zone

- Extended life in the highest wearing section of the furnace

- Reduced maintenance and repair requirements

- Low total cost of ownership

FAQ

How many rows of impact bricks should a furnace have?

The optimum height of the impact section depends on several factors, particularly the charging frequency used at the facility. Saint-Gobain Performance Ceramics & Refractories’ extensive expertise with copper shaft furnaces enables the provision of optimal designs for any refractory system, including appropriate sizing of the impact zone.

Which product is recommended as a backing material behind the impact zone?

The choice of castable backing material for the impact zone of a furnace will vary depending on the specification of the furnace and application. Saint-Gobain Performance Ceramics & Refractories’ experienced engineering teams are on hand to provide customer-focused advice and support around this.

Documents

Related Content

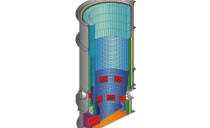

Primary and Secondary Copper Furnaces

Refractory materials from Saint-Gobain Performance Ceramics & Refractories offer excellent performance and extended service life in the most critical...

Holding Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Launders

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractory solutions for molten metal transfer.

Shaft Furnace

Discover Saint-Gobain Performance Ceramics & Refractories’ industry-leading refractory system for copper shaft furnaces.

Related Products

Hot Face Bricks

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of silicon carbide hot face bricks for copper furnaces.

Burner Blocks and Burner Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of burner blocks and burner tubes for copper furnaces.

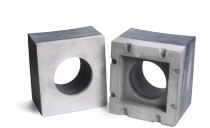

Tap Hole Blocks

Discover Saint-Gobain Performance Ceramics & Refractories’ leading tap hole system for copper furnaces.

Back-up Safety Lining

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of backup safety linings for copper furnaces.

Firefrax CRM-30 and Carbofrax Series - Mortars

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of specialty mortars for copper furnaces.

Belly Brick System

Discover Saint-Gobain Performance Ceramics & Refractories’ belly brick system - straightforward protection for single tube walls with no metallic fixing...

Launder Hot Face

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of launders, troughs and tundish refractory components.