Both of these materials are fine-grained and produced to near theoretical density, ensuring excellent wear resistance required for seal face products.

Both materials possess outstanding resistance to corrosion from chemicals with a wide range of pH values. Seal faces are produced to custom drawings with high quality surface finishes.

Features and Benefits

- Exceptional hardness

- Chemically inert to a broad range of chemicals

- Seal faces for mechanical seals used in industrial pumps

| Physical Properties | Units | SA |

| Composition (phases) | SiC | |

| Density | g/cm3 | 3.15 |

| Grain Size | Qm | 4-10 |

| Hardness (Knoop)** | kg/mm2 | 2800 |

| Flexural Strength 4pt. @ RT*** | MPa x103 lb/in2 | 380 55 |

| Flexural Strength 3pt. @ RT*** | MPa x103 lb/in2 | 550 80 |

| Compressive Strength @ RT | MPa x103 lb/in | 3900 560 |

| Modulus of Elasticity @ RT | GPa x106 lb/in | 430 62 |

| Weibull Modulus (2 parameters) | 10 | |

| Poisson Ratio | 0.14 | |

| Fracture Toughness @ RT Double Torsion & SENB | MPa x m½ 103lb/in2 x in½ | 4.60 4.20 |

| Coefficient of Thermal Expansion RT to 700°C | x10-6mm/mm°K x10-6in/in°F | 4.02 2.20 |

| Max. Service Temp (air) | °C °F | 1900 3450 |

| Mean Specific Heat @ RT | J/gm°K | 0.67 |

| Thermal Conductivity @ RT | W/m°K Btu/ft h°F | 125.6 72.6 |

| @ 200°C | W/m°K Btu/ft h°F | 102.6 59.3 |

| @ 400°C | W/m°K Btu/ft h°F | 77.5 44.8 |

| Permeability RT to 1000°C | All impervious to gases over 31 MPa | |

| Electrical Resistivity @ RT*** @ 1,000°C | ohm-cm | 102-108 0.01-0.2 |

| Emissivity | 0.9 |

* Composition code: Si = free silicon metal; C = free graphite; SiC = silicon carbide

* Knoop 100-gm load

*** Test Bar Size: 3 x 4 x 45 mm (0.118" x 0.157" x 1.772")

*** Dependent upon dopants in Hexoloy® SA SiC which will decrease electrical resistivity

| Physical Properties | Units | Value |

| Composition* | Si • N | |

| Grain Size | µm | < 2 |

| Density | g/cm3 | 3.18 |

| Hardness (Vickers)** | GPa | 16 |

| Flexural Strength 4 pt @ RT*** | MPa | 800 |

| Compressive Strength @ RT | MPa | 3500 |

| Modulus of Elasticity @ RT | GPa | 320 |

|

Fracture Toughness @ RT Indentation |

MPA x m1/2 | 4.2 |

| Color | gray | |

|

Coefficient of Thermal Expansion RT to 1,000°C |

x10-6 mm/mmK | 2.9 |

| Thermal Conductivity @ 100 °C | W/mK | 29 |

| Electrical Resistivity @ RT*** | ohm-cm | > 1012 |

| Purity | % | |

| Si3N4 | 95 | |

| Al | 0.35 | |

| C | 0.50 | |

| Ca | 0.01 | |

| Fe | 0.02 | |

| Mg | 0.60 | |

| O | 2.5 | |

| Other | trace |

* Composition code: Si = Free silicon metal, N = Nitrogen, Si3N4 = Silicon Nitride

** Vickers 10 kg load

*** TestBar Size: 3 x 4 x 45 mm (0.118" x 0.157" x 1.772")

Documents

Industries Served

Automotive and Electric Vehicles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of solutions for the automotive market.

Chemical

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics solutions for the chemical market.

Nuclear Energy

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of advanced ceramic products for the nuclear energy industry.

Related Products

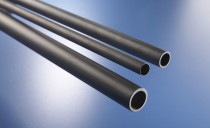

Hexoloy Seal Tubes

Hexoloy® SA sintered silicon carbide seal tubes are available in a wide range of OD and ID combinations. Seal tubes are unground and sold with “as-fired”...

Hexoloy Seal Blanks

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics for mechanical seals.

Probes for Industrial Gas Sensors

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic probes for industrial gas sensors.