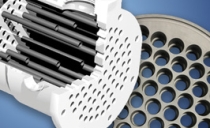

Hexoloy® SE silicon carbide tubes are the most reliable choice for shell and tube heat exchangers employed in fine and specialty chemicals, offering virtually universal corrosion resistance, high thermal conductivity, extremely high hardness and excellent mechanical strength.

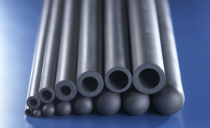

Hexoloy® SE sintered silicon carbide tubes are extruded products, available in 8 mm, 12.7 mm, 14 mm and 19 mm outer diameters, and lengths up to 4.5 m. Tubes are used in conjunction with tube sheets (PTFE, PFA lined steel, or SiC) and a series of baffles placed inside a steel or glass shell.

Tubes undergo a rigorous quality control and inspection process, including hydrotesting of every tube at 165-186 bar. Hexoloy® SE tubes have exceptionally thin walls, resulting in high heat transfer when used in a heat exchanger application.

Hexoloy® SA silicon carbide tube sheets are also available in a range of diameters and thicknesses.

- Non-fouling

- High strength

- Ultra-long service life

- Excellent thermal conductivity

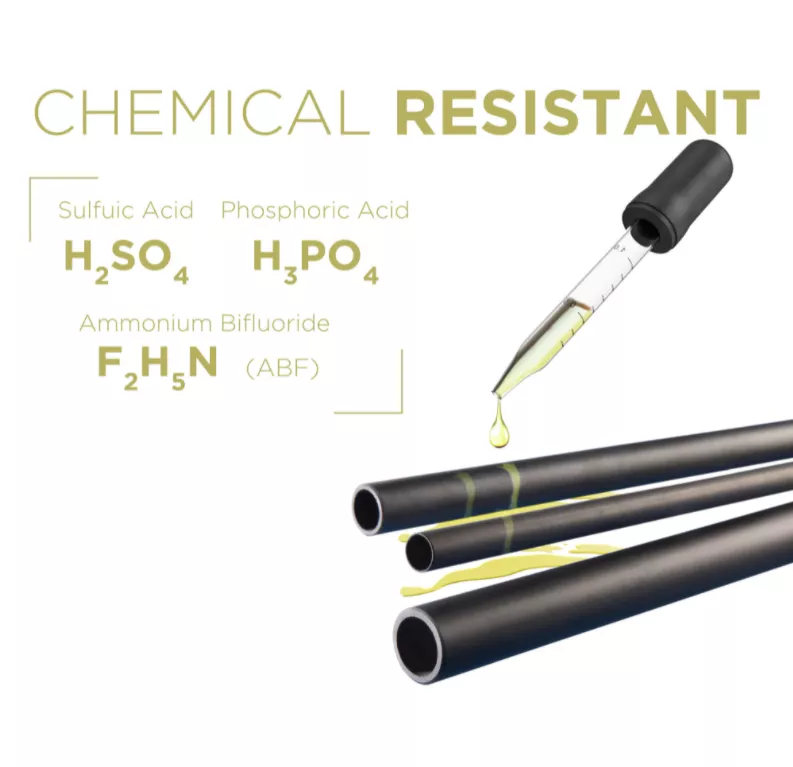

- Universal corrosion resistance

- Extreme hardness and wear resistance

- Lowers operating and maintenance costs over the life of the product Improves efficiency by reducing down time and maintenance

- Meets strict chemical industry standards worldwide

| Physical Properties | Units | SE |

| Composition (phases) | SiC | |

| Density | g/cm3 | 3.05 |

| Grain Size | microns | 4-10 |

| Hardness (Knoop)* | kg/mm2 | 2800 |

| Flexural Strength 4pt. @ RT | MPa x103 lb/in2 | 280 40 |

| Compressive Strength @ RT | MPa x103 lb/in | 3900 560 |

| Modulus of Elasticity @ RT | GPa x106 lb/in | 420 60 |

| Weibull Modulus (2 parameters) | 10 | |

| Poisson Ratio | 0.14 | |

| Fracture Toughness @ RT Double Torsion & SENB | MPa/√m 103b/in2/√in | 4.60 4.20 |

| Coefficient of Thermal Expansion RT to 700°C | x10-6mm/mm°K x10-6in/in°F | 4.02 2.20 |

| Max. Service Temp (air) | °C °F | 1900 3450 |

| Mean Specific Heat @ RT | J/gm°K | 0.67 |

| Thermal Conductivity @ RT | W/m°K Btu/ft h°F | 157.3 90.9 |

| @ 200°C | 107.2 62.0 | |

| @ 400°C | 77.3 44.7 | |

| Permeability RT to 1000°C | All impervious to gases over 31 MPa | |

| Electrical Resistivity @ RT*** @ 1000°C | ohm-cm | 102-108 0.01-0.2 |

| Emissivity | 0.9 |

* Knoop 100-gm load

*** Dependent upon dopants in Hexoloy SE SiC that will decrease electrical resistivity to a desired range.

N/A = Not applicable or not available

Hexoloy® SE sintered silicon carbide tubes are extruded product available in 8 mm, 12.7 mm, 14 mm, and 19 mm outside diameter, and lengths up to 4.5 m. Tubes are used in conjunction with tube sheets (PTFE, PFA lined steel, or SiC) and a series of baffles placed inside a steel or glass shell.

FAQ

What are the key benefits of using Silicon Carbide Tubes?

Hexoloy® Silicon carbide is essentially inert to a wide range of corrosive chemicals, including strong acids and caustics, up to 200°C. Most alternatives, such as graphite, metals, alloys, introduce contamination over time from corrosion. Other key benefits include high heat transfer, superior mechanical strength, and low thermal expansion.

Does Saint-Gobain Performance Ceramics & Refractories offer fully assembled heat exchangers?

No. Saint-Gobain Performance Ceramics & Refractories sells its products to heat exchanger OEMs for construction and assembly.

How well do silicon carbide tubes perform against fouling liquids?

Silicon carbide tubes are known to offer good resistance to fouling.

What is the difference between Hexoloy® SE and Hexoloy® SA SiC?

Both are pressure-less sintered Silicon Carbide materials. Whereas SA grade is iso-pressed or dry-pressed, SE grade is extruded.

Documents

Industries Served

Chemical

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics solutions for the chemical market.

Hexoloy SE Sintered Silicon Carbide Tubes and SA Tube Sheets

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide products for shell and tube heat exchangers.

Related Products

Hexoloy® SE Thermocouple Protection Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for thermocouple sensor protection.

Silit SK SiSiC Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for thermocouple and gas sensor protection.

Alundum and Magnorite Crushable Insulators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for Mineral Insulated Metal Sheathed (MIMS) thermocouple protection.