Features and Benefits

Benefits

Applications

- Corrosion resistance

- Thermal shock resistance

- Oxidation resistance

- Extended campaign life

| Product | Product Use |

| ALFRAX® 65 TCN | Standard product for low aggressive conditions |

| ALFRAX® 70 TCP | Special product designed for metal lines |

| ALFRAX® 75 TCP | High-performance Al2O3-SiC-C brick for working lining |

| ALFRAX® 75 TCN | High purity raw material with excellent mechanical strength |

| ALFRAX® 75 TCE | Outstanding corrosion resistance during De-S processes |

| ALFRAX® 75 TSR | Excellent thermal shock and spalling resistance |

FAQ

Why do Saint-Gobain Performance Ceramics & Refractories’ ACS bricks offer such high thermal shock resistance?

ACS bricks’ thermal shock resistance is due to a combination of carefully selected high quality raw materials designed to ensure the perfect thermal balance; and an engineered structure with a high degree of stress attenuation. This combination allows equipment to move through thermal cycles while suffering very little damage to its inner structure, ensuring a long service life.

Related Content

Equipment

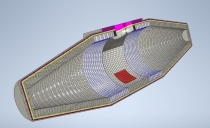

Torpedo Car (Torpedo Ladle)

Discover Saint-Gobain Performance Ceramics & Refractories’ range of engineered refractories – suitable for a wide range of pig iron treatment and transport...