Key Benefits of NORPHOS™ Dephosphorization Solution

- Compliant with IS1786 for construction steel

- High-quality, low phosphorus steel

- No capital expenditure necessary

- Comprehensive solution with lining, flux, and engineering support

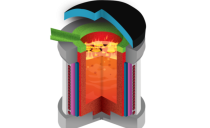

Our NORPHOS™ solution is tailored to meet the dephosphorization requirements of coreless induction furnaces, adapting to specific operational conditions for optimal efficiency. We provide customized refractory linings and fluxes that integrate seamlessly into your existing processes, ensuring efficient phosphorus removal and high-quality steel production.

NORPHOS™ solutions are ideal for coreless induction furnaces, offering tailored refractory linings and fluxes to enhance the dephosphorization process. Our products, including NORVIBE™ A 150 and NORPHOS™ F 150, are designed to perform under high-temperature conditions, effectively capturing excess phosphorus.

Want to Know More?

Contact our experts to learn more about our high-efficiency dephosphorization solutions. Click the button below to complete a short form, and allow us to do the rest.

FAQ

What type of equipment modification is required for low-phosphorous steel production?

No additional investments are needed. The NORPHOS™ solution allows for seamless production of low-phosphorous steel by adding NORPHOS™ F 150 flux during melting operations.

What flux and refractory lining mix are recommended?

NORPHOS™ F 150 flux, combined with NORVIBE™ A 150 or NORVIBE™ A 1248 LG refractory linings, ensures efficient dephosphorization and extends furnace campaign life.

What are favorable conditions for dephosphorization?

Favorable conditions for steel-making dephosphorization include high temperatures, reducing slag viscosity, maintaining optimal basicity, and using efficient fluxes to capture phosphorus.

Documents

Related Content

Foundry

Saint-Gobain Performance Ceramics & Refractories leverages its extensive expertise to provide innovative, reliable refractory solutions for all ferrous and...

Coreless Induction Furnace

Saint-Gobain Performance Ceramics & Refractories’ extensive portfolio of solutions for coreless induction furnaces supports customers to enhance safety and...

Inductor

Saint-Gobain Performance Ceramics & Refractories offers a specialized product portfolio designed to significantly reduce metal penetration and leakage...

Ladle & Other

Saint-Gobain Performance Ceramics & Refractories offers a number of solutions designed to ensure the safety, efficiency and easy installation of ladles and...

Pouring Furnace

Saint-Gobain Performance Ceramics & Refractories offers solutions for a wide range of pouring and holding furnaces, taking into account factors such as...

Related Products

NORFIX Mortar and Cement Mixes

Saint-Gobain Performance Ceramics & Refractories’ NORFIX™ products include refractory mortar and cement mixes which have been developed to meet customer...

NORSHAPE Pre-Shaped Refractories

NORSHAPE™ products exhibit a homogeneous and strictly controlled microstructure, helping extend furnace service life and reducing metal contamination...

NORCOIL Cement Mixes

Saint-Gobain Performance Ceramics & Refractories’ NORCOIL™ range of coil cement mixes is specifically designed to protect the coil in coreless induction...

NORFAST Fast-firing Castables

Saint-Gobain Performance Ceramics & Refractories’ NORFAST® fast-firing mixes feature a special bonding system formulated to increase drying speed whilst...

HeatKing Monolithic Lining

HeatKing™ range of high performance refractory products are designed for use in extreme operating conditions, delivering enhanced performance.

NORPATCH Patching Mixes

Saint-Gobain Performance Ceramics & Refractories’ NORPATCH™ range includes a large choice of patching mixes for quick, efficient and long lasting furnace...

NORGUN Gunning Mixes

Saint-Gobain Performance Ceramics & Refractories’ NORGUN™ range incorporates a wide range of gunning mixes designed for furnace maintenance and repair.