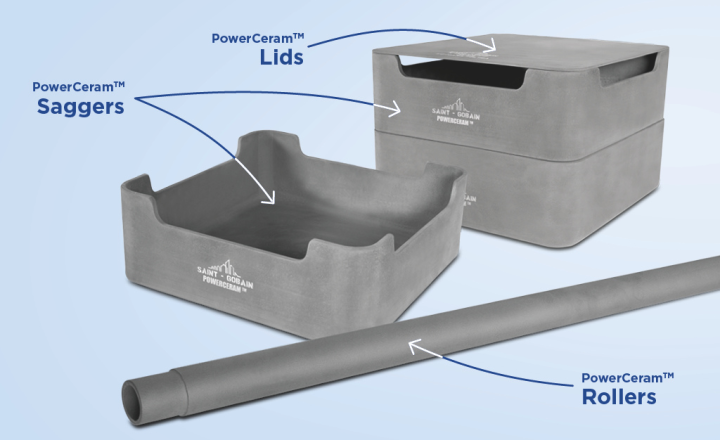

PowerCeram™ Ceramics

PowerCeram™ ceramics revolutionize cathode active material (CAM) production

Advanced ceramic solutions designed for thermal shock and chemical corrosion resistance.

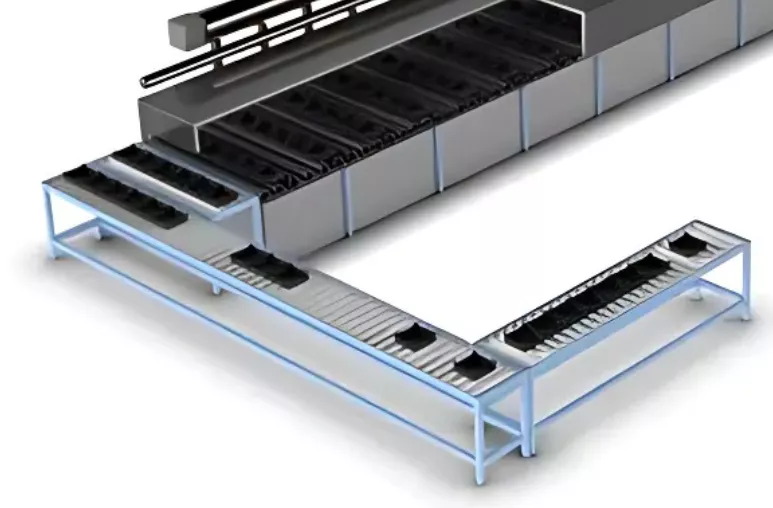

PowerCeram™ in use - case study: Construction of a new plant

End User Inputs

- Production Capacity,

- CAM Powder chemistry.

Kiln Builder Inputs

- Automation needs,

- temperature profile,

- sagger rows,

- CAM powder load.

PowerCeram™ Solution

- Recommendation of the ideal roller material.

- Optimization & customization of roller (slot, hole, partial cut, inner machining, etc.).

Result

- A custom-tailored, high-performance solution for efficient and reliable operations.

Contact us for more information on PowerCeram™

PowerCeram™ Solutions aren’t just products – It’s a smarter path forward for CAM producers. Our skilled engineers are happy to answer your questions.

The unique benfits of PowerCeram™ Ceramics

Quality, cost-effectiveness, and efficiency for businesses in battery material production.

Recycling of SiC Ceramics – our action plan

INTERNAL RECYCLING

We target 100% reuse of green and fi red process scrap across all sites.

EOL REFURBISHMENT

We offer SiC product take-back programs in Europe, including recycling and refurbishment for select markets.

EOL RECYCLING

Saint-Gobain has developed lab-scale SiC recycling processes (e.g., saggers & rollers) and seeks partners for pilot-scale implementation.