Exploration des avantages des solutions de masses de bourrage neutres (NRM)

En ingénierie métallurgique, notamment dans les fours à induction, l'accent est mis sur une analyse comparative entre les masses de bourrage neutres (NRM) et la silice afin d'optimiser l'efficacité et la sécurité de vos installations. Cet article explore les masses de bourrage neutres (NRM), en mettant particulièrement en avant les solutions proposées par Saint-Gobain sous notre marque HeatKing/NORTON, tout en soulignant leurs avantages par rapport aux matériaux conventionnels tels que les masses de bourrage acides (à base de silice).

Ces solutions sont adaptées à tous les types de charges, comme le minerai de fer réduit (pellets, morceaux, fines), la ferraille d'acier (de toutes sortes), la fusion directe d'acier inoxydable ou d'autres alliages, ainsi qu'à toutes les capacités de fours à induction sans noyau.

Bénéfices EHS (Environnement, de Santé de Sécurité)

1. Réduction des risques liés à la silice : Le premier avantage de l'utilisation des masses de bourrage neutres (NRM) concerne la santé. En effet, les NRM ne contiennent pas de silice cristalline alvéolaire. Cette poussière de silice, connue pour provoquer des maladies pulmonaires graves, constitue un risque sanitaire majeur dans les environnements industriels. La réglementation de l'Occupational Safety and Health Administration (OSHA) 29 CFR 1926.1153 encadre strictement l'exposition à la poussière de silice, soulignant sa dangerosité. La composition des NRM élimine ce danger, offrant ainsi une alternative plus sûre pour les applications industrielles.

2. Absence de pollution des sols et utilisation durable : Les déchets de silice traditionnelle nuisent à la fertilité des sols en raison de leur nature. À l'inverse, les NRM n'affectent pas la fertilité lorsqu'ils sont jetés à même le sol. La silice a des possibilités de recyclage très limitées, tandis que les NRM peuvent être entièrement recyclées et réutilisées pour d'autres applications après leur utilisation complète dans les fours à induction. Cette réutilisabilité réduit la génération de déchets et, par conséquent, diminue le recours aux décharges et la pollution des sols.

Avantages généraux

Exigences de stockage optimisées : La durée de vie prolongée des masses de bourrage neutres (NRM) réduit la fréquence des relingages et des opérations de maintenance. Par conséquent, cela nécessite moins de matériaux à stocker sur site, optimisant ainsi l'utilisation de l'espace dans les installations de stockage.

Réduction des pannes opérationnelles : La robustesse des NRM se traduit par une diminution des pannes dans les opérations des fours, ce qui améliore la productivité globale et réduit les interruptions imprévues.

Facilité de maintenance préventive : La durabilité des NRM facilite la maintenance préventive des creusets alternatifs, permettant un fonctionnement continu avec un minimum de perturbations.

Efficacité en termes de main-d'œuvre et de temps : La durée de vie prolongée des masses de bourrage neutres (NRM) réduit la fréquence des opérations de maintenance et de remplacement. Cette efficacité permet de réaffecter les ressources humaines à d'autres tâches critiques, optimisant ainsi la gestion du temps et des efforts dans les processus industriels.

Amélioration de la Qualité

L'acier produit à l'aide d'un revêtement en NRM s'est révélé plus pur comparé à celui produit avec d'autres mélanges de bourrage.

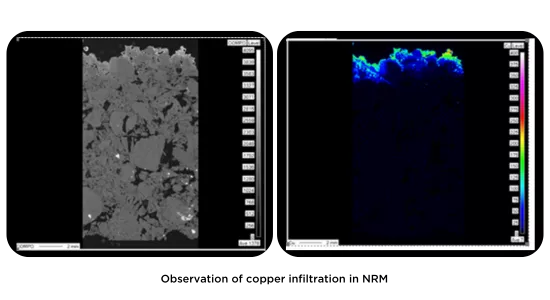

Observations microscopiques de l'infiltration métallique – "Test de la coupe" :

Le "test de la coupe" est une méthode utilisée pour analyser l'infiltration de métal dans les matériaux NRM. Le processus se déroule comme suit : Le matériau réfractaire monolithique (NRM) est pressé sous forme de brique avec une petite cavité au centre. Cette cavité est remplie avec le métal à étudier. L'ensemble est chauffé à une température donnée pendant plusieurs heures afin de faire fondre le métal. Une fois refroidie, la brique est coupée en deux pour évaluer l'infiltration du métal dans le matériau NRM.

Moins l'infiltration est importante, meilleure est la performance du NRM. De plus, de plus petits échantillons peuvent être découpés pour examiner l'infiltration métallique au microscope, fournissant une analyse détaillée de la qualité et de l'efficacité du matériau.

Avantages économiques

Contenu Relatif

Solutions de fonderie : pisé sec NRM vs. Revêtement à base de silice

Les fabricants s'efforcent de maintenir un niveau élevé de qualité finale grâce à des solutions de fonderie innovantes et rentables, en revêtant...

Besoin d'en savoir plus?

Les solutions de masses de bourrage neutres, en particulier celles proposées par Saint-Gobain sous la marque HeatKing/NORTON, représentent un changement de paradigme dans le revêtement des fours à induction. Leur profil de sécurité supérieur, leurs avantages environnementaux, leurs gains d'efficacité opérationnelle et leurs bénéfices pour la santé en font une alternative privilégiée aux revêtements traditionnels à base de silice.

À mesure que les industries évoluent vers des pratiques plus sûres, plus durables et plus efficaces, l'adoption des NRM témoigne des avancées technologiques dans les solutions réfractaires.

Contactez dès maintenant nos experts pour explorer les opportunités de développement qui vous attendent. Cliquez sur le bouton ci-dessous pour remplir le formulaire, et nous serons ravis de vous accompagner dans votre parcours.