Revolutionizing EV Battery Production with PowerCeram™ Saggers

As the demand for electric vehicles (EVs) surges, the need for efficient, sustainable, and cost-effective battery manufacturing solutions has never been greater. One crucial element in the production of lithium-ion battery cathodes is the use of saggers, which play a vital role in sintering cathode active materials (CAM). Saint-Gobain Performance Ceramics & Refractories has developed an innovative solution – PowerCeram™ saggers – that is redefining the standards of performance, sustainability, and efficiency in CAM processing.

Enhanced Efficiency and Higher Throughput

PowerCeram™ saggers are designed to optimize kiln capacity, allowing for increased production output without requiring additional capital investment in new equipment. Their lightweight construction and thin-walled design enable more efficient stacking and higher CAM powder loads per cycle. As a result, manufacturers can expect an increase in throughput on existing kiln systems, significantly boosting productivity while maintaining consistent quality.

Superior Thermal and Chemical Resistance

Traditional saggers made of mullite and cordierite often suffer from thermal shock and chemical degradation over time, leading to increased downtime and maintenance costs. PowerCeram™ saggers, crafted from high-strength silicon carbide (SiC), offer exceptional thermal shock resistance and superior chemical durability. Their high corrosion resistance minimizes contamination and material loss, ensuring that CAM powders maintain their purity throughout the sintering process.

Energy Savings and Reduced CO2 Emissions

Energy consumption is a major cost driver in battery material production. PowerCeram™ saggers are engineered to significantly reduce energy usage by enhancing kiln efficiency. The advanced SiC material improves thermal conductivity, reducing the energy required to heat the kiln furniture. This could lead to more than 50% of energy savings per kilogram of CAM produced, directly translating into lower CO2 emissions of equivalent savings per production cycle and a smaller environmental footprint for battery manufacturers.

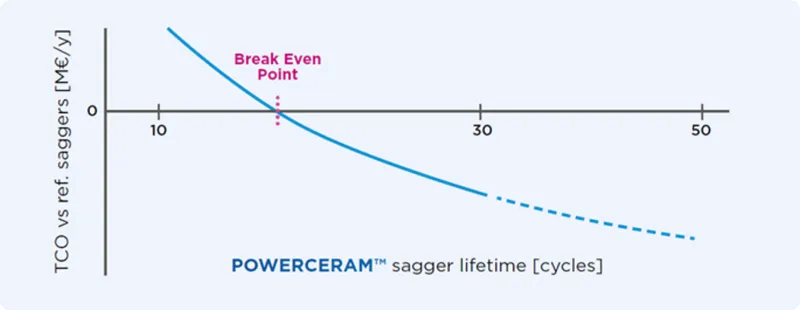

Extended Service Life and Cost Savings

One of the most compelling advantages of PowerCeram™ saggers is their exceptional cycle life, which can be 2-3 times longer than conventional oxide-based saggers. This longevity reduces the frequency of replacements, minimizing both material waste and operational downtime. Additionally, Saint-Gobain's Total Cost of Ownership (TCO) calculator helps businesses estimate long-term savings, showcasing how investing in PowerCeram™ saggers can drive substantial cost efficiencies. Customers have reported TCO savings of over 25% compared to traditional solutions.

Sustainability Through End-of-Life Recycling

Saint-Gobain is committed to sustainability, and PowerCeram™ saggers support this mission by offering end-of-life recycling programs. Instead of contributing to landfill waste, used saggers can be refurbished and reintroduced into production, further reducing the environmental impact and dependency on raw materials. With internal recycling initiatives and take-back programs available, manufacturers can align their operations with circular economy principles, reducing ceramic waste by up to 50% while maintaining high-performance standards.

Future-Proofing EV Battery Manufacturing

With the increasing push towards green energy solutions and sustainable manufacturing, battery producers must adopt advanced materials that enhance efficiency while reducing environmental impact. PowerCeram™ saggers are setting a new industry benchmark by offering higher productivity, lower energy consumption, superior durability, and comprehensive recycling solutions.

For battery manufacturers looking to maximize their production efficiency, lower operational costs, and contribute to a greener future, PowerCeram™ saggers present the ultimate solution.

PowerCeram™ Lids: Strength, Fit, and CAM Protection

PowerCeram™ product solution is also featuring cover lids that fit perfectly well with the saggers and ensure that no pollution from outside would impact the CAM purity. Our lids are manufactured to have minimum 3mm thickness by keeping their incredible mechanical resistance and can be used for a long time, as per their excellent resistance against bending.

Want to know more?

Achieve your goals with our customized industrial ceramic solutions. Contact us today to learn more!

Related Content

PowerCeram

Advanced ceramic solutions designed for thermal shock and chemical corrosion resistance.

PowerCeram Saggers

Explore the benefits and features of PowerCeram® Saggers for CAM Processing.