Zirconia Ceramics: What are They & How are They Used?

With that said, one ceramic material you should consider using is zirconium dioxide (ZrO2), otherwise defined as zirconia or zirconium oxide. Zirconia ceramics are renowned for their extensive capabilities.

Not only are they extremely strong and can have a density of around 6.1 g/cm^3, but they have excellent wear resistance. In fact, zirconia ceramics have the ability to change their size under different heats and avoid forming cracks. As a result, this material has been labeled as “ceramic steel.”

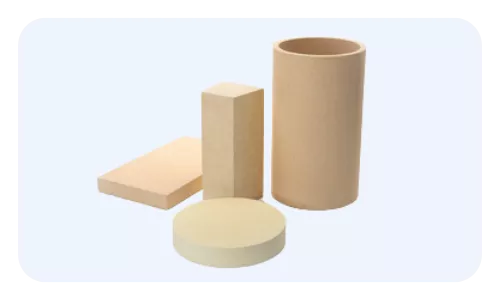

Zirconia ceramics are created through calcination and are used in a variety of applications, like in the creation of watches, oxygen sensors, photocatalysts, tubes in furnaces, and nozzles that are used in sandblasting tools.

Of course, these are only a few examples of the characteristics and uses of zirconia ceramics. It is an extremely versatile type of ceramic, therefore it can be applied to many other areas. If you are interested in learning more about the uses and properties of zirconia ceramics, we invite you to read on.

Below you will find more detail on zirconia ceramics. By the time you have finished reading, you should know if this is the ceramic material for you!

The Unique Properties of Zirconia Ceramics

Crystal Structure and Mechanical Properties

The mechanical properties of zirconia are deeply influenced by its crystal structure. Zirconia exists in three primary polymorphic forms:

- Monoclinic

- Tetragonal

- Cubic

At room temperature, pure zirconia is found in the monoclinic phase. However, it transitions to tetragonal and cubic phases at high temperatures. The ability to maintain the tetragonal phase at room temperature through the addition of stabilizers, such as yttria, leads to what is known as yttria partially stabilized zirconia (Y-PSZ). This variant exhibits transformation toughening.

Thermal Expansion and Thermal Stability

Zirconia's thermal expansion properties are closely aligned with its thermal stability. Unlike many ceramic materials, zirconia's thermal expansion coefficient is similar to that of some metals. This means it can be used in diverse thermal environments without the risk of stress failure because of mismatched expansion rates.

This property, combined with high thermal stability, makes zirconia an ideal choice for applications subjected to high temperatures

High Density and Fine Grain Structure

The high density and fine grain structure of zirconia contribute to its outstanding mechanical properties. This includes its high bending strength and wear resistance. Its fine grain structure also allows for a smoother surface finish and improved strength, as the small grains provide less space for crack propagation.

These properties make zirconia particularly valuable in areas requiring durability and resistance to mechanical wear.

Applications in Engineering Ceramics and Thermocouple Protection Tubes

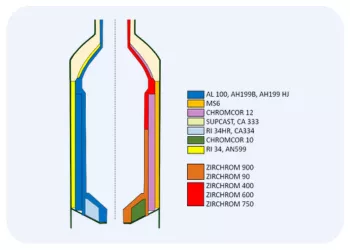

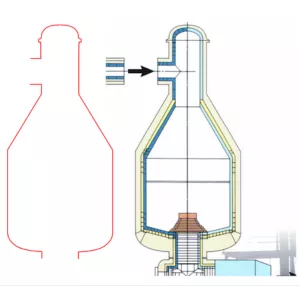

- Its resistance to high temperatures and thermal shock is especially valuable in industries such as aerospace and automotive engineering. In these industries, materials are regularly exposed to harsh operating conditions.

- For thermocouple protection tubes, zirconia's ability to withstand high temperatures while maintaining chemical stability is crucial. These tubes protect thermocouples from the extreme conditions often encountered in industrial processes, ensuring accurate temperature measurements are maintained. Zirconia's low thermal conductivity also helps to prevent thermal gradients that could lead to measurement errors.

Are You Ready to Utilize the Benefits of Zirconia Ceramics?

As you can see, zirconia ceramics contain excellent properties that can be implemented in a wide variety of areas. From using it in pads and tubes, to more extensive applications in lasers, insulators, sensors, kilns, and fuel cells, zirconia ceramics can be relied upon because of their ability to withstand heat and chemicals.

Additionally, zirconia ceramics are extremely strong and can avoid damage that can occur because of corrosion. They are also hard and can resist the transfer of heat and electricity.

With their extensive capabilities and applications, it is not surprising that the market for zirconia ceramics is going to be worth around $3.80 billion in 2032. The future is bright for zirconia ceramics. As we consider how this material could be developed, we should look at two specific pathways in particular.

One potential application for zirconia ceramics relates to the creation of greener energy. As zirconia ceramics do not affect the environment, there is the possibility that they could be used in tools that could contain energy. The other future pathway for zirconia ceramics could be as a material for three-dimensional printers.

Now that you understand the characteristics and applications of zirconia ceramics, are you ready to use them? If you are, you should look at the zirconia ceramics that we, Saint-Gobain Refractories, have to offer. We have a variety of grades of zirconia ceramics available that can be applied in your work and research.

Browse our selection of zirconia ceramics on our website. We also have other types of ceramic materials available, such as alumina, mullite, and magnesia, and even specialty ceramics. As ceramic experts, we can help you find suitable materials that will fit your intended purpose. That way you can utilize their capabilities to the fullest extent.

Zirconia ceramics are renowned for their useful attributes. So, do not pass up on this opportunity to try them out for yourself. Wherever you apply it, the properties of zirconia ceramics will ensure that they will remain robust against the challenges you set for them.

Related Content

Enhancing CAM Powder Calcination with Ceramic Rollers: A Silit® Solution

Discover how Silit® ceramic rollers from Saint-Gobain Performance Ceramics & Refractories enhance CAM powder calcination for lithium-ion battery production...

What Advantages Do Ceramic Loops Offer?

Explore the NORLOOP™, a groundbreaking precast ceramic loop by Saint-Gobain, enhancing furnace efficiency, safety, and longevity in industrial processes.

Want to know more ?

Contact us today for more information on zirconia ceramics. We are ready to help you locate the perfect ceramic.