Ultra-High Temperature Ceramics for Extreme Environments

Ultra-high temperature ceramics (UHTCs) are a specialized subset of ceramic materials, distinguished by their ability to retain structural integrity at temperatures exceeding 1,400°C. Unlike conventional ceramics, UHTCs are engineered for specific high-temperature applications, offering a reliable alternative when traditional materials are susceptible to degradation.

Is it integral for materials engineers to understand the fundamentals of the solutions available, particularly given the multifaceted challenges facing industries today. Novel solutions like ultra-high-temperature ceramics can provide a robust foundation for meeting performance requirements, addressing sustainability challenges, and optimizing production processes.

A Technical Deep Dive into UHTCs

Silicon Carbide (SiC)

Within the UHTC category, Silicon Carbide (SiC) is a prominent material. SiC is recognized for its exceptional chemical and mechanical properties, especially at elevated temperatures. Noteworthy attributes of SiC include its high strength, hardness, and thermal conductivity. Additionally, SiC offers resistance to corrosion and thermal shock, making it suitable for diverse applications in sectors like aerospace, defense, and energy. Some of the specific high-temperature applications of SiC include:

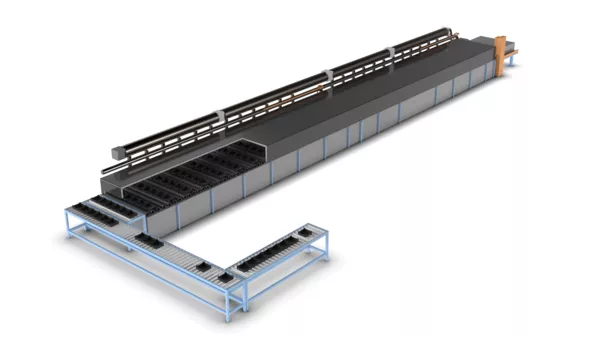

- Hot Stamping Rollers: SiC ceramics are integral in the production of hot stamping rollers, capitalizing on their inherent high-temperature strength and thermal shock resistance.

- Thermocouple Protection Tubes: In furnaces and other high-temperature settings, SiC is employed to fabricate thermocouple protection tubes, safeguarding thermocouples from extreme temperatures.

- Temperature Sensors: Hexoloy, a variant of silicon carbide, is utilized to shield temperature sensors in environments characterized by harshness and corrosivity. Owing to its minimal coefficient of thermal expansion, Hexoloy can endure temperatures as high as 1,950°C under special atmospheres.

- Heat Exchangers: Hexoloy SE, a specialized type of SiC, is particularly adapted for heat exchangers, high-temperature furnaces, chemical processing, and other applications that demand resilience in severe conditions.

- Semiconductor Applications: The semiconductor industry values SiC for its pronounced chemical inertness, making it the material of choice for wafer handling and inspection.

- New Energy Applications: The chemical corrosion resistance, strength, and wide variety of forming methods available for SiC materials allows for high performance at lower thickness (<3mm) at elevated temperatures relative to other material options. This optimizes performance in the production of cathode active material (CAM) and SOFC/SOEC plates.

Zirconia (ZrO2)

Zirconia (ZrO2) is another significant UHTC. It is particularly valued for its fracture toughness and controlled thermal expansion properties.

Zirconia's resistance to thermal shock and its ability to maintain mechanical properties at high temperatures make it a preferred choice for applications such as thermal barrier coatings, advanced cutting tools, and biomedical implants.

Saint-Gobain's Contribution: Hexoloy®

Impact and Advancements with UHTCs

The integration of UHTCs, notably SiC and Zirconia, has facilitated advancements in industries operating under extreme conditions. These ceramics contribute to operational efficiency and extend the durability of equipment. By leveraging UHTCs, industries can enhance current methodologies and develop innovative technological solutions.

The Role of UHTCs in Future Developments

We are dedicated to pioneering innovations in ceramics. We encourage stakeholders to explore our comprehensive range of solutions, fostering collaborations that drive industrial progress.