Steel industries

Steelmaking through Coreless Induction furnace

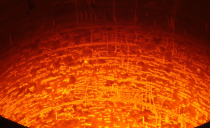

In steel production, Induction furnaces have become increasingly essential, especially in places like South Asia and Africa where there's a big demand for steel products. In the last ten years, we've seen more and more factories with multiple induction furnaces popping up, showing just how important they are in meeting the growing need for steel.

To keep these furnaces running smoothly, you need top-notch materials. That's where Saint-Gobain Performance Ceramics & Refractories products and application engineering play a vital role. We've got a range of advanced products designed specifically for induction furnace operations - from small 50KG furnaces to those over 50 tons. Our team of experts has set examples with many of our esteemed customers.

For optimum performance, our solutions go through rigorous quality procedures, helping our customers achieve maximum life in any lining application.

Interested to know our products for your Induction furnace? Click here to connect!

Why Choose Saint-Gobain's Refractory Solutions?

Our materials make furnace linings last longer, so you won't have to replace them as often.

Our expert engineers are deployed at your site to help you optimize lining application and achieve longer campaign life.

We perform rigorous data analysis to identify the root cause of any past failures in your induction furnace and provide the right solution at any given operation.

We help you have less downtime and fewer maintenance issues, meaning your factory can keep running smoothly.

By optimizing the steelmaking process, our solutions contribute to sustainability efforts, minimizing waste and energy consumption.

Usage of our products helps in minimizing the risk of silicosis, one of the major concerns for people working on the shop floor. Usage of HeatkingTM Neutral Ramming Mass (NRM)also significantly reduces the risk of accidents on the shop floor because of refractory lining failure thus ensuring safety of the people while also protecting the machineries.

Induction furnace - HeatKing™

Saint-Gobain Performance Ceramics & Refractories leverages its extensive expertise to provide innovative, reliable refractory solutions for all ferrous and...

Working Linings

Saint-Gobain Performance Ceramics & Refractories’ extensive portfolio of solutions for coreless induction furnaces supports customers to enhance safety and...

Furnace Top and Spout

Saint-Gobain Performance Ceramics & Refractories’ extensive portfolio of solutions for coreless induction furnaces supports customers to enhance safety and...

Coil Coat

Saint-Gobain Performance Ceramics & Refractories’ extensive portfolio of solutions for coreless induction furnaces supports customers to enhance safety and...