Next Generation Refractory Solutions for Steelmaking through Coreless Induction Furnace

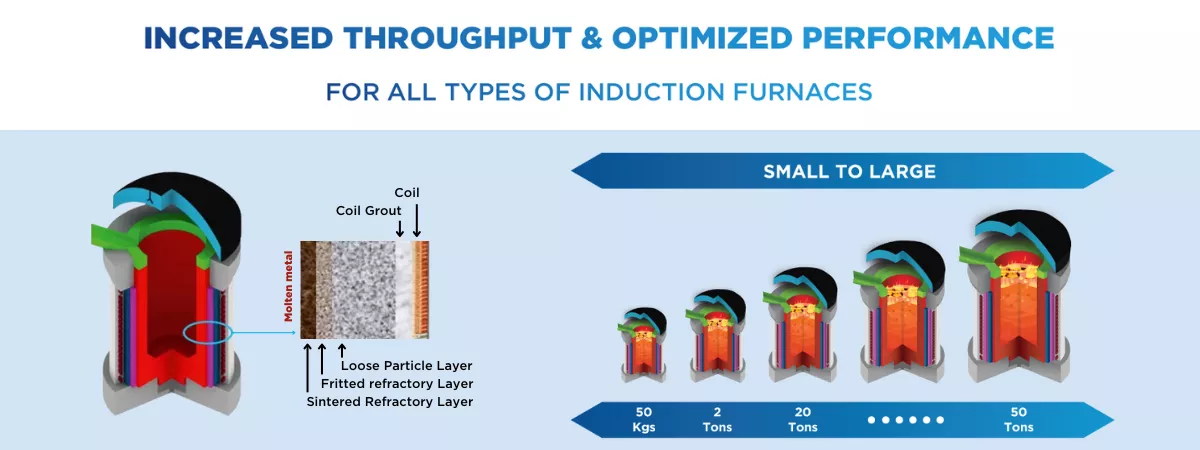

HeatKing™ introduces an advanced monolithic lining solution designed to optimize steel melting processes in coreless induction furnaces. Its unique structure guarantees superior steel quality, reduced cost per unit, improved productivity, enhanced safety, energy efficiency, and sustainability.

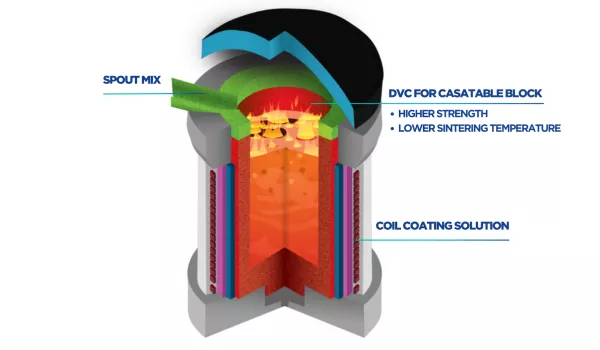

Our HeatKing™ range includes solutions for working linings, furnace tops, spouts, and coil coatings, enabling customers to operate with maximum efficiency and reliability.

Interested in our Products, application engineering or lining services? Click here to connect!

Solution By Application

Click on your application to find more:

- Working Linings

- Furnace Top and Spout

- Coil Coat

Neutral Ramming Mass for Working Linings of Induction Furnace

The HeatKing™ product range has been specifically designed and developed to accommodate the Indian market’s local requirements. HeatKing™ solutions are adapted for the melting of steel in coreless induction furnaces using scrap or DRI as feedstock.

HeatKing™ presents an innovative monolithic lining solution with a unique structure, delivering the best performance in terms of steel quality, cost, productivity, safety, energy efficiency and sustainability.

HeatKing™ Benefits

QUALITY

Higher metal purity due to less "inclusions" ensuring quality in-line with the BIS Standards.

PRODUCTIVITY

Clear increase in productivity on account of...

• Longer life and less downtime

• Optimization of former design.

COST

Lower cost per unit mass of Hot Metal produced on account of...

• 4 to 5 times higher campaign life with the option of multiple "patchings"

• More efficient Alloy Recovery

• Possibility to keep Hot Heel in Furnaces thus decreasing heat duration.

• Less power consumption

• Lower labour requirements.

ENERGY EFFICIENCY & SUSTAINABILITY

Unique lining structure that ensures lower power consumption (less CO2 footprint) thanks to...

• Optimized powder back-up lining leading to minimal conduction loss

• Optimized lining thickness leading to maximum induction heating.