Next Generation Refractory Solutions for Steelmaking through Coreless Induction Furnace

HeatKing™ introduces an advanced monolithic lining solution designed to optimize steel melting processes in coreless induction furnaces. Its unique structure guarantees superior steel quality, reduced cost per unit, improved productivity, enhanced safety, energy efficiency, and sustainability.

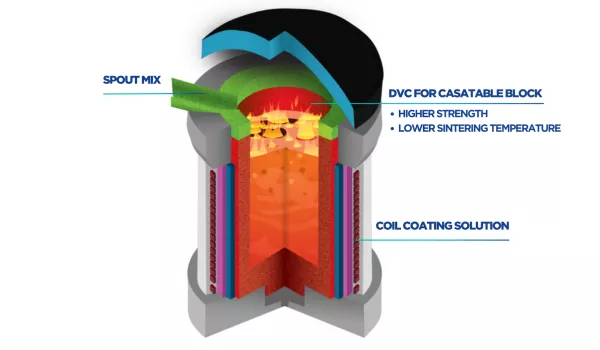

Our HeatKing™ range includes solutions for working linings, furnace tops, spouts, and coil coatings, enabling customers to operate with maximum efficiency and reliability.

Interested in our Products, application engineering or lining services? Click here to connect!

Solution By Application

Click on your application to find more:

- Working Linings

- Furnace Top and Spout

- Coil Coat

Advanced Refractory solutions for Induction furnace Coil Protection

Saint-Gobain Performance Ceramics and Refractories also offers fused alumina-based refractory solutions for coil grouting in coreless induction furnaces.

Specifically formulated to provide exceptional protection and insulation for the induction coils, this product is crucial for efficient furnace operation. The high-grade fused alumina used in our coil coat ensures excellent thermal conductivity and mechanical strength, making it highly effective in shielding the coils from extreme temperatures and mechanical wear.

The coil coat solution is easy to apply, creating a uniform and protective layer that enhances the longevity of the induction coils. By reducing the thermal load on the coils, our refractory solution helps to:

- Maintain optimal furnace performance and prevent premature coil failure.

- Improve energy efficiency and reduce maintenance requirements.

- Lower operational costs and enhance productivity.

- Ensure long-term reliability.